Cement Packing Machine

Cement Packing Machine Introduction

The cement packaging machine is a mechanical device used for the automatic packaging of cement. It can receive cement from storage tanks and automatically fill it into bags, completing a series of packaging processes such as sealing and label printing. At the end of the cement production line, it is a crucial component that can greatly improve production efficiency and packaging quality.

Cement Packing Machine Types

Cement packaging machines are part of the complete set of cement production plants, AGICO supplies it mainly in 2 types: fixed and rotary. Fixed-type cement packaging machines are 1-4 nozzle packaging machines, where bags are manually inserted for cement filling. Rotary-type cement packaging machines have 6-14 nozzles, and the machine rotates to complete bag insertion and filling without manual intervention. Currently, the fixed-type cement packaging machine is more commonly used in rotary kiln cement enterprises. Adopts with mechanical filling, where cement is injected or extruded into cement paper bags by high-speed rotating "cross" shaped blades or spiral blades. The bags are discharged when they reach a certain weight (usually 50 kg ± 11 kg).

Rotary Cement Packer

Rotary Cement Packer Fixed Cement Packer

Fixed Cement PackerCement packing machine is a side filling style rotary packing machine with 8 spouts, weighing controlled by micro-computer, impeller feeding style.Model BHYW8CQ Rotary Cement Packing Machine is mainly used for packing cement; meanwhile, it also may be used for filling bulk materials of powder and granule.

There are 4 models of rotary cement packing machine: 6CQ(with 6 spouts, capacity 90t/h), 8CQ(with 8 spouts, capacity 120t/h) , 10CQ(with 10 spouts, capacity 120-140t/h), 12CQ (with 12 spouts, capacity 140-160t/h)

Cement Packing Machine Operation Environment:

- Temperature: -10~40°C

- Relative humidity: < 90%

- Altitude: < 2000m

- Moisture content: <1%

- Packing temperature: <120°C

- Density: Generic 1.1~1.3t/m3

Rotary Type Cement Package Machine Customized Model

Rotary-type Cement Packer Specification

| Parameter | Unit | Models | |||||

|---|---|---|---|---|---|---|---|

| BHYW6C | BHYW8C | BHYW10C | BHYW12C | ||||

| value | |||||||

| Discharging mouthPCs | 6 | 8 | 10 | 12 | |||

| Packing capacity | bag/h | 1200—1800 | 1800—2200 | 2200—2600 | 2600—3000 | ||

| Weighing accuracy | 95% weight error | Kg | +0.6 -0.2 | ||||

| Bag weight pass rate | % | ≥95 | |||||

| 20 bag total weight | kg | 1000~1004 | |||||

| Diameter of rotating drum | mm | Φ1560 | Φ1750 | Φ2090 | |||

| Maximum diameter of rotation | mm | Φ2200 | Φ2400 | Φ2740 | |||

| mounting height above the floor(discharge mouth) | mm | 1350 | |||||

| Rotating barrel speed | r/min | 0-6 | |||||

| Rotating direction | Overlook | clockwise or counterclockwise | |||||

| Power voltage | V | 380±10% AC | |||||

| Motor | models | Y112M-4 | |||||

| power kw | 4×6=24 | 4×8=32 | 4×10=40 | 4×12=48 | |||

| rotation rate | 1440 | ||||||

| Rotating barrel drive | YVP | models | YVPE90L-4 | ||||

| Power kw | 1.5 | 2.2 | |||||

| rotate speed r/min | 125-1250 | ||||||

| reducer | models | XLDV-4 | |||||

| speed ratio | 1:43 | ||||||

| bleed pressure | MPa | 0.1-0.2 | |||||

| Dust collecting air volume | M3/h | >9000 | >12000 | >18000 | >24000 | ||

| Total weight | t | 4.32 | 5.2 | 5.7 | 6.2 | ||

|

Overall dimensions Length (upper beam) x width x height |

mm | s3800×2200×4000 |

4000×2400 ×4000 |

4500×2740 ×4000 |

|||

Fixed Type Cement Packer Specification

| Model | AG-1Q | AG-2Q | AG-3Q | AG-4Q |

|---|---|---|---|---|

| Qty of spout(piece) | 1 | 2 | 3 | 4 |

| Loading capacity(t/h) | 15 | 30 | 45 | 60 |

| One bag weighing precision(kg) | Microcomputer balance 50±0.35 | |||

| Eligibility rate of a bag weight(%) | ≥95 | |||

| Continous 10 bags of average weight error | +0.24 -0.08 | |||

| Motor power(kw) | 4 | 2×4 | 3×4 | 4×4 |

| Feeding motor power(kw) | 1.5 | 2.2 | ||

| Power supply voltage(v) | 380%(AC) | |||

| Collecting dust air Qty(m3/h) | 2000 | 4000 | 6000 | 8000 |

| Whole set weight(t) | 0.558 | 0.885 | 1.21 | 1.573 |

| Size(with feeder) (L×W×H) mm | 580×1300×1780 | 1050×1300×1780 | 1640×1300×1780 | 1990×1300×1780 |

Fixed Type Cement Packer Structure:

The structure of a fixed-type cement packaging machine mainly consists of 8 parts: the feeding device, discharge chamber, transmission shaft, machine body, discharge control mechanism, fixed weight frame, packaging frame, and discharge outlet. It is known for its simplicity of structure, ease of operation, and low energy consumption.

Supporting Equipments of Cement Packer

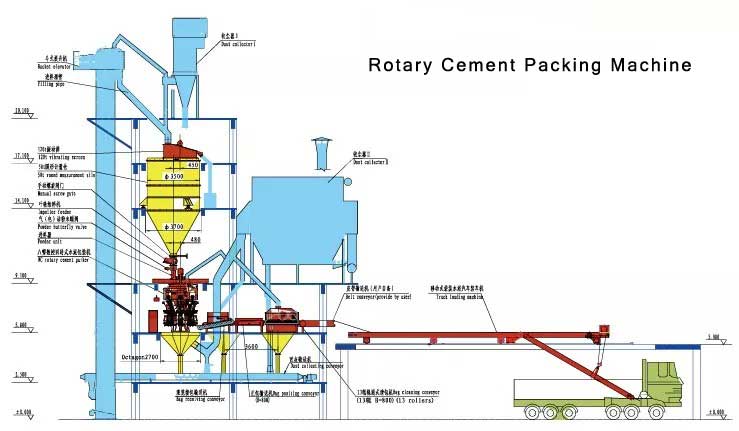

Supporting equipment for rotary-type cement packaging machines includes a vibrating screen, screw gate, feeder, chute, packaging machine mainframe, bag-receiving conveyor, positive-pressure bag conveyor, bag cleaning conveyor, simple weight sensor, level controller, and more, depending on the specific requirements of the cement plant.

Working Principle of Cement Packaging Machine:

- Startup Procedure: Power on – Start conveyor belt – Start packaging machine – Start feeder – Insert bags – Fill bags – Measure – Drop bags.

- Shutdown Procedure: Turn off feeder – Empty cement from the packaging machine – Turn off the main power.

Features of Cement Packaging Machine:

- Wide applicability: Suitable for packaging powdery and granular materials with good flowability.

- Automation: Achieves automation in filling, measuring, and bag dropping.

- Clean and environmentally friendly: Ensures a clean and eco-friendly working environment, with bags not inserted or filled if the weight is below the set value. If bags accidentally fall off, the gate immediately closes to stop filling.

- Simple maintenance: Easy to maintain with few vulnerable parts, and it does not use hydraulic or pneumatic components.

Cement Packing Machine Features:

- Accurate weighing, lower energy consumption;

- Great packing capacity and easy maintenance;

- Realize functions of bag mouth pressing and releasing, opening and closing flashboards, falling bag down automatically without any pneumatic components, reduce a lot of troubles caused by pneumatic components damage.

BHYW8C Rotary Cement Packing Machine

| No | Parameter Name | Unit | Data | No | Parameter Name | Unit | Data | |||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Number of nozzles | pc | 8 | 17 | Main drive motor | Model | Y90L-4 | |||

| 2 | Design packing ability | t/h | 120 | Power | kW | 1.5 | ||||

| 3 | Filling style | Side feeding | Rotate speed | r/min | 1450 | |||||

| 4 | Discharging style | Impeller | Protection level | IP44 | ||||||

| 5 | Weighing mechanism style | Microcomputer scale | 18 | Discharging motor | Model | Y112M-4 | ||||

| 6 | Weighing precision | Single weight | kg | 50 | Power | kW | 4 | |||

| 95% Single bag weight error | kg |

+0.4 -0.2 |

Rotate speed | r/min | 1450 | |||||

| Total weight of consecutive 20 bags | kg | 1000~1004 | Protection level | IP44 | ||||||

| 7 | Outer diameter of rotary bin | mm | φ1560 | Quantity | pc | 8 | ||||

| 8 | Outer diameter of discharging nozzle | mm | φ2200 | 19 | Double position solenoid driver | Model | MQZ2-50-300 | |||

| 9 | Distance from discharging nozzle to ground | mm | 1300 | Power | V | 200 | ||||

| 10 | The max. rotary diameter | mm | φ2320 | Rated travel range | mm | 50 | ||||

| 11 | Main driver speed adjusting style | Frequency control | Frequency | t/h | 360 | |||||

| 12 | Range of speed adjusting | r/min | 0-6 | 20 | Whole power | kW | 33.5 | |||

| 13 | Rated rotate rate of the machine | r/min | 5 | 21 | Dust collection air flow | m³/h | 17000 | |||

| 14 | Power supply | AC 380V 3P 50Hz | 22 | Dust collection air pressure | Pa | -600 | ||||

| 15 | Power fluctuation | % |

+10 -15 |

23 | Rotary direction of the machine | Over head view | Clockwise | |||

| 16 | Main drive reducer motor | Model | BLD3-59-1.5 | 24 | Overall height | mm | 5460 | |||

| Speed ratio | 59 | 25 | Overall weight | kg | ||||||