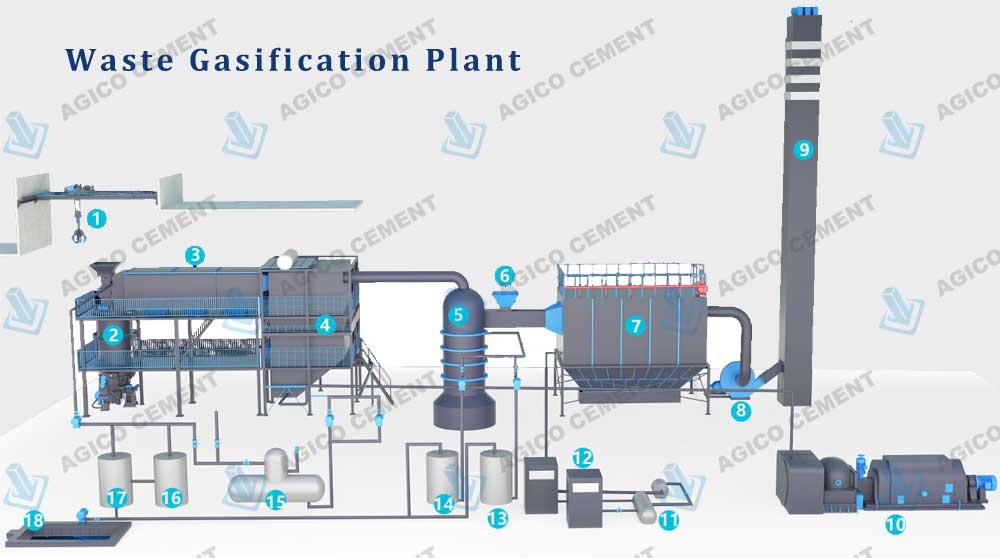

Waste Gasification Plant

Waste Gasification Plant Introduction:

Waste gasification plant adopts pyrolysis machine as the gasifier, create high temeperature environment for waste to turn into activated carbon, heat, electricity and other byproducts, it is a sustainable and eco-friendly solution for waste treatment. The waste types for gasification covers industrial waste, household waste, hospital waste.

AGICO is able to design and supply gasification plant equipment for treatment of various type of waste. The complete waste gasification plant is consisted with 3 main parts: raw material pretreatment, pyrolysis and gasification, waste gas treatment.

Waste Gasifier - Pyrolysis Machine

Waste Gasifier - Pyrolysis MachineBiomass Gasification Furnace Technical Parameter

| Category | Classification | AG-XL1500 | AG-LX1800 | AG-LX2000 | AG-LX2200 | AG-LX2400 | AG-LX2600 | AG-LX3000 |

|---|---|---|---|---|---|---|---|---|

| Fuel | Material consumption (KG) | 80-140 | 160-280 | 300-400 | 500-600 | 900-1000 | 1200-1500 | |

| granularity | Wood chips: 3O-5Omm, plant straw 4100mm | |||||||

| Moisture content | 20% | |||||||

| Biomass Gas | Theoretical yield (MD | 240-320 | 480-680 | 900-1200 | 1200-1400 | 1600-1800 | 2200-2600 | 2800-3200 |

| Gas calorific value | 1100-1300cal/m5 | |||||||

| Performance | Vaporization rate M3/KG | Woody: 2-3m3 Herb: 1-1.5m3 | ||||||

| By Product | Each ton of raw materials can produce about 200-400kg of charcoal, 30g of tar, and 250kg of wood vinegar. | |||||||

| Biomass Composition Ratio | ||||||||

| Gas Type | CO | H2 | CH4 | CO2 | N2 | O2 | CmHn | H2s |

| Content Ratio | 10-25% | 10-13% | 2-4% | 13% | 46% | 1% | 0.8% | 16.4mg/Nm3 |

Biomass Gasification Funance Profit Analyze

| Serial Number | Project | Sub Option | Quantity(kg/h) | Unit price RMB (kg/h) | It consumes a lot of money | Consumption RMB/month | Consumption of 10,000 RMB/year | Total | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Consume | Wood Chips | 2000 | 0.3 | 14400 | 43.2 | 432 | 432 | |

| Output | Biomass Charcoal | 400 | 0.8 | 7680 | 23.04 | 230.4 | 311.04 | ||

| 2 | Wood Tar | 40 | 0.8 | 768 | 2.304 | 23.04 | |||

| Wood Acetic Acid | 400 | 0.2 | 1920 | 5.76 | 57.6 | ||||

| Annual expenditure: 432-311.04=1.2096 million RMB | |||||||||

| Traditional Energy | Monthly net profit after savings (10,000 RMB) | Annual net profit after savings (10,000 RMB) | |||||||

| Diesel Fuel | 288.13-12.1=276.03 | 2760.3 | |||||||

| Heavy Oil | 218.28-12.1=206.18 | 2061.8 | |||||||

| Natural Gas | 177.66-121 = 165.56 | 1655.6 | |||||||

The calculation reveals an annual profit of 7.847 million RMB, based on a project investment of 15 million RMB. The investment can be recouped in 2 to 3 years (Note: The above parameters are calculated based on a 1 MW electricity generation capacity and the related project costs are for reference only).

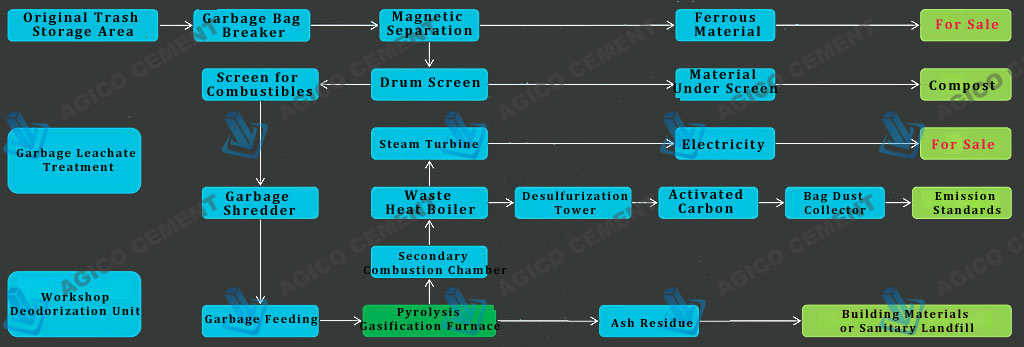

Waste Gasification Plant Working Process (Heat and Electricity Generation)

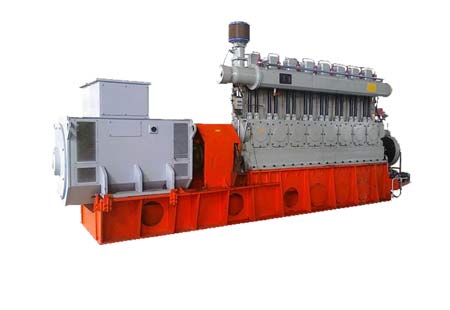

Biomass Gasification Generator Set

Biomass Gasification Power Set

Raw waste materials are pre-processed to remove inorganic materials such as glass, iron, stones, sand, etc. The waste is then fed into the pyrolysis gasification furnace using a grab bucket. The pyrolysis gas is combusted in the secondary combustion chamber at temperatures exceeding 1000°C, with a gas residence time of N2s, effectively breaking down harmful gases, including dioxins. The high-temperature flue gas provides heat to the waste heat boiler, producing steam to drive a steam turbine/screw expander generator for electricity generation.

The exhaust gas is purified through an acid removal tower, activated carbon, and a dust collector to meet emission standards (GB18485-2014) before being released. (Suitable for small to medium-sized waste processing)

Waste Gasification vs. Traditional Waste Treatment:

-

Environmental Benefits: Waste gasification offers a more environmentally friendly approach compared to traditional incineration and landfilling. Instead of emitting harmful pollutants into the atmosphere, gasification processes waste materials in a controlled environment, producing fewer emissions and minimizing the impact on air quality. This results in reduced greenhouse gas emissions and contributes to cleaner air.

-

Resource Recovery: Unlike conventional disposal methods, waste gasification doesn't just dispose of waste; it converts it into valuable resources. The process can generate electricity, heat, or biofuels while recovering metals and reducing waste volume. This resource recovery aspect adds an economic incentive to waste gasification, making it a viable alternative to landfilling.

-

Versatility: Waste gasification can handle a wide range of feedstocks, including municipal solid waste, industrial waste, agricultural residues, and even hazardous materials. This versatility sets it apart from traditional treatment methods that often require specific waste streams.

-

Reduced Land Use: Landfills are a significant contributor to land scarcity and habitat disruption. Gasification significantly reduces the need for landfills, freeing up valuable space and reducing the environmental impact of waste disposal.

-

Lower Operating Costs: Gasification can be more cost-effective in the long run. While the initial investment may be higher than traditional methods, the energy and resource recovery aspects, coupled with reduced environmental compliance costs, can lead to significant savings over time.

-

Community Acceptance: Waste gasification systems can be designed to minimize odors and noise, addressing some of the concerns that often lead to community resistance against landfills and incinerators. This makes it easier to gain community acceptance for waste management projects.

Gasification Technology

Gasification is a thermochemical process that converts various types of solid or liquid organic waste materials into valuable gaseous products. This technology offers an environmentally sustainable and resource-efficient approach for managing waste while simultaneously producing useful energy and chemicals. Gasification can be applied to a wide range of waste types, including biomass, municipal solid waste (MSW), industrial residues, and hazardous waste, resulting in diverse final products.

Waste Types Suitable for Gasification:

-

Biomass: Biomass feedstocks such as agricultural residues, forestry waste, and dedicated energy crops can be gasified to produce biofuels like syngas (a mixture of hydrogen and carbon monoxide), which can be further converted into electricity, heat, or biofuels.

-

Municipal Solid Waste (MSW): Gasifying MSW can help reduce the volume of waste sent to landfills, while producing syngas and other valuable products. This approach offers a sustainable method for waste management and energy recovery.

-

Industrial Residues: Various industrial byproducts and residues, such as plastic waste, rubber, and coal fines, can be gasified to generate syngas or other chemicals, reducing the environmental footprint of waste disposal.

-

Hazardous Waste: Gasification can be employed to treat hazardous waste materials, breaking them down into less harmful substances, while capturing and controlling emissions. This process helps minimize environmental risks and pollution.

Final Products of Gasification:

-

Syngas (Synthesis Gas): Syngas is the primary product of gasification, comprising a mixture of hydrogen (H2), carbon monoxide (CO), carbon dioxide (CO2), and other trace gases. Syngas can be used directly as a fuel for power generation or further processed into a range of valuable chemicals and fuels.

-

Electricity and Heat: Syngas can be burned in gas turbines, engines, or boilers to generate electricity and heat. Combined heat and power (CHP) systems are commonly used to maximize energy efficiency.

-

Biofuels: In the case of biomass gasification, the syngas can be converted into biofuels such as synthetic natural gas (SNG), biodiesel, or bioethanol through downstream processes like Fischer-Tropsch synthesis or catalytic conversion.

-

Chemical Feedstocks: Syngas can serve as a precursor for the production of chemicals such as methanol, ammonia, and other industrial gases. These chemicals have diverse applications in the chemical industry.

-

Char and Ash: Gasification leaves behind solid residues, primarily char and ash. Char can be used as a carbon source for various applications, including soil amendment and carbon sequestration. Ash may be disposed of or processed for recovery of valuable minerals.

-

Emissions Control: Gasification processes typically incorporate advanced emission control technologies to minimize environmental impact. This includes the capture and treatment of pollutants like sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate matter.