Cement Seperator

- Application: In cement industry production, in order to improve the efficiency of the grinding system and reduce the energy consumption of the product, a circulating grinding system is now widely used. As an important part of the system, the advanced performance of the classifier directly affects the efficiency of the system. Therefore, the research and development of the classifier has always been valued by various research institutes and industrial and mining enterprises.

- Material: Non-metallic powder material

- Cement Seperator Types: JD series, TS series, TZX series

Cement Seperator Description:

JD series seperator is high-efficiency combined raw material special powder sorting machine, which is the latest type of powder sorting equipment developed, combined with advanced powder classify technology to apply the plane eddy current theory to the cyclone type separator. Powder selection efficiency reaches 80-85%, fineness adjustment is convenient and flexible, and the performance is stable and reliable in cement plant.

Technical Parameter of Seperator

JD series cement powder separator technical parameters

| Specifications and specifications | AG JD500-S | AG JD800-S | AG JD1000-S | AG JD1500-S | AG JD2000-S | AG JD2500-S | |

|---|---|---|---|---|---|---|---|

| Matching mill specifications | Φ2.2 | Φ2.6 | Φ3.0 | Φ3.2 | Φ3 | Φ3.8 | |

| Spindle speed | 190-300 | 150-260 | 130-260 | 120-240 | 120-240 | 120-210 | |

| Production capacity | 27-51 | 41-78 | 54-88 | 78-135 | 108-154 | 130-185 | |

| Fineness (80μm sieve) | 8%-10% | ||||||

| Reducer | model | B2SV4-5-B | B2SV5-5.6-B | B2SV5-5.6-B | B2SV6-6.3-B | B2SV6-6.3-B | B2SV7-7.1-B |

| Speed ratio | 5 | 5.6 | 5.6 | 6.3 | 6.3 | 7.1 | |

| Motor | model | Y200L-4 | Y225S-4 | Y250M-4 | Y280S-4 | Y315S-4 | Y315M1-4 |

| Power kw | 30 | 37 | 55 | 75 | 110 | 132 | |

| Circulation fan | model | C6-48N012.5C | 4-72N1616B | 4-72NO16B | 4-72NO20B | 4-72NO20B | G4-73NO25D |

| Speed rm | 1120 | 900 | 950 | 680 | 710 | 580 | |

| Wind pressure a | 3038 | 2741 | 2788 | 2771 | 2609 | 3236 | |

| Air volume m3/h | 66388 | 111929 | 136004 | 165164 | 210210 | 232000 | |

| motor model | Y280S-4 | Y315S-4 | Y315M-4 | Y315M1-4 | Y315M3-4 | Y450-54-10 | |

| Motor power kw | 75 | 110 | 132 | 185 | 220 | 280 | |

| Dry pump specifications | GYZ-8 | GYZ-8 | GYZ-8 | GYZ-8 | GYZ-8 | GYZ-8 | |

TS series cement powder separator technical parameters

| name | Specification model | TS-I(250) | TS-II(350) | TS-III(500) | TS-IV(750) | TS-V(1000) | TS-VI(1250) | TS-VII (1500) | TS-VIII(1750) | TS-IX |

|---|---|---|---|---|---|---|---|---|---|---|

| Spindle | AG YCTL225-4B | AG YCTL250-4A | AG YCTL250-4B | AG YCTL280-4A | AG Y200L-4 | AG Y225M-4 | AG Y225M-4 | AG Y250M-4 | AG Y280S-4 | |

| power | 15 | 18.5 | 22。 | 30 | 30 | 37 | 45 | 55 | 75 | |

| 150-400 | 150-350 | 150-320 | 140-320 | 130-280 | 130-260 | 120-240 | 110-200 | 110-180 | ||

| Fan | Fan model | 9-26NolOC | 9-26N012.5O | 9-26Nol2.5G | SCF-12Nol4G | SCF-12Nol4B | SCF-12Nol6B | SCF-12Nol6B | SCF-12Nol8G | SCF-12Nol8B |

| Rotating speed | 1000 | 1080 | 1130 | 1100 | 1200 | 1050 | 1200 | 1050 | 1200 | |

| Full pressure | 5920 | 4921 | 486 as | 5764 | 5384 | 5582 | 5862 | 6272 | 5865 | |

| Air volume | 21465 | 30533 | 41021 | 46796 | 61280 | 76040 | 96631 | 120740 | 154910 | |

| motor model | Y225M-4 | Y250M-4 | Y280S-4 | Y280M-4 | Y315Ml-4 | Y315M2-4 | Y315M2-4 | Y355L-4 | Y355M-4 | |

| power | 45 | 55 | 75 | 90 | 132 | 160 | 200 | 250 | 315 | |

| ability | Product fineness | 0-3 | 0-3 | 0-3 | 0-3 | 0-3 | 0-3 | 0-3 | 0-3 | 0-3 |

| Handling air volume | 16000 | 22000 | 30000 | 45000 | 60000 | 75000 | 95000 | 120000 | 150000 | |

| Maximum throughput | 50 | 90 | 120 | 150 | 210 | 260 | 330 | 400 | 500 | |

| Generating ability | 10-18 | 15-28 | 20-40 | 30-50 | 40-70 | 50-85 | 75-110 | 95-130 | 130-160 | |

| Dimensions | Height (mm) | 5160 | 5450 | 5750 | 6200 | 6700 | 7000 | 7870 | 8320 | 8530 |

| Maximum outer diameter | Φ3600 | Φ4100 | Φ4500 | Φ5000 | Φ5600 | Φ6200 | Φ6500 | Φ7000 | Φ7300 | |

| Standard military halo | 7.2t | 9.3t | 10.5t | 12.8t | 19t | 24杪 | 28t | 33t | 38t |

TZX series cement powder separator technical parameters

| AG TZX-400 | AG TZX-500 | AG TZX-600 | AG TZX-700 | AG TZX-800 | AG TZX-900 | AG TZX-1000 | ||

|---|---|---|---|---|---|---|---|---|

| Production (t/h) | cement | 12—16 | 18—22 | 20—26 | 28—35 | 45—54 | 64—76 | 85—105 |

| Raw material | 16—20 | 21—28 | 30—35 | 35—46 | 55—65 | 80—90 | 110—130 | |

| Product fineness | cement | 2-6 | 2-6 | 2-6 | 2-6 | 2-6 | 2-6 | 2-6 |

| Raw material | 8—10 | 8—10 | 8—10 | 8—10 | 8—10 | 8—10 | 8—10 | |

| Spindle (r/min) | 。 | 190—380 | 190—380 | 150—350 | 130—320 | 130—320 | 130—320 | 110—280 |

| Spindle motor | model | YCTL180—4A | YCTL200-4B | YCTL225-4A | YCTL225-4B | YCTL280—4A | YCTL315-4A | YCTL335-4A |

| Speed (r/min) | 125—1250 | 125—1250 | 125—1250 | 132—1320 | 132—1320 | 132—1320 | 132—1320 | |

| Power (Kw) | 4 | 7.5 | 11 | 15 | 22 | 37 | 55 | |

| Circulation fan | model | 。 | 。 | 。 | 。 | 。 | 。 | 。 |

| Air volume (m3/h) | 21373 | 32427 | 39437 | 67650 | 75200 | 91200 | 168000 | |

| Wind pressure (Pa) | 2367 | 2302 | 2302 | 2355 | 2325 | 2479 | 2700 | |

| Motor | Y180-2 | Y200L—2 | Y225M — 4A | Y250M — 4A | Y280S-4 | Y300L—6 | Y300K-6 | |

| Power (Kw) | 15-18.5 | 22—30 | 37 | 55 | 75 | 110 | 132 | |

Performance Characteristics:

The main features of the classifier are low energy consumption, large processing capacity, and flexible combination structure: it can be interchanged with the fluidized bed crushing machine to become a crushing classifier, and can be used with a rake mill, a ball mill, a roller mill, etc.

Combine and separate the ultrafine powder, which has the functions of low energy consumption and low pollution; it can be directly connected with dryers, conveyor belts, automatic packaging machines, etc., simplifying the production process and steps. Use of ultra-segmented grades that cannot be graded on common seperating equipment, especially for products that are strictly limited to the largest particles and require a narrow particle size distribution, such as heavy calcium, kaolin, talcum powder, barite powder, paint, Mica, graphite, auxin, aluminum hydroxide, etc. It can classify materials that require extremely strict grain size and meet the requirements of purity and grain shape. Typical materials: copier toner, laser printer powder, mobile phone battery powder, industrial battery powder, etc.

Working Principle of Cement Seperator:

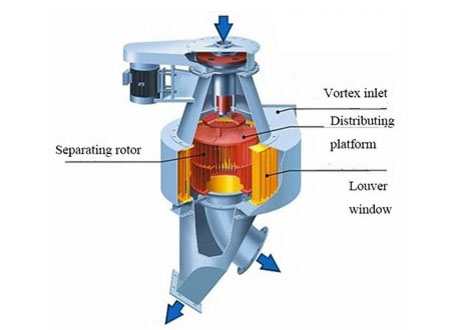

The classification chamber of the cyclone type separator is a cylindrical casing made of steel plate. In classification chamber, the small blades and the spreading disc are fixed together on the vertical axis. The motor is rotated by belt conveyor in the classification chamber. Strong centrifugal force is formed, and gas powder mixture entering the classification chamber is subjected to the centrifugal force.

The large or heavy particles are subjected to centrifugal force, so they are smashed to edge, no longer affected by the centrifugal force. it is collected, and then discharged as coarse powder through coarse powder tube; small or light material is less affected by centrifugal force, hovering inside the grading room, being carried to height by air flow, and moving to the next component along the pipeline It is graded or collected, and speed of the centrifugal force can be adjusted by the frequency converter to adjust speed, so as to separating the materials of the specified granularity.