Rotary Kiln

- Applications: Widely used in many production industries such as non-ferrous metallurgy, ferrous metallurgy, chemical industry, cement, refractory materials, lime, environmental protection, etc.

- Materials: mineral granules and powders such as clay, limestone, dolomite, iron ore, chromite, ceramsite sand, zinc oxide, bauxite, alumina, aluminum hydroxide, fly ash, high alumina refractories, etc. Material

- Equipment Size: Φ1.6*20, Φ1.9/1.6*36, Φ2.8/2.5*55, Φ3.0*48, Φ3.3*52, Φ3.95*56, Φ3.95*56, Φ4.2*60, Φ4.8*74.

Cement Rotary Kiln Description:

Rotary kiln can be divided into Cement Kiln, Metallurgical Chemical Kiln, Lime Kiln, Ceramsite Kiln, Zinc Oxide Kiln, etc. The cement rotary kiln is mainly used for calcining cement clinker, dry process to produce cement kiln and the wet process to produce cement kiln; the metallurgical chemical kiln is mainly used for magnetization roasting of iron ore mine in metallurgical industry; chrome and ferronic oxide oxidizing roasting, Chlorination and roasting roasting method for extracting tin and lead

refractory plant roasting high alumina bauxite ore and aluminum plant roasting clinker, aluminum hydroxide; chemical plant roasting chrome ore and chrome ore and other minerals; lime kiln for roasting steel active lime and light burnt dolomite used in factories, ferroalloy plants, calcium carbide plants, metal magnesium plants; ceramic kiln used in bauxite, clay, yellow mud, river bottom sludge, fly ash, shale, coal gangue, Calcination and production of various materials such as municipal solid waste, biological sludge, etc.

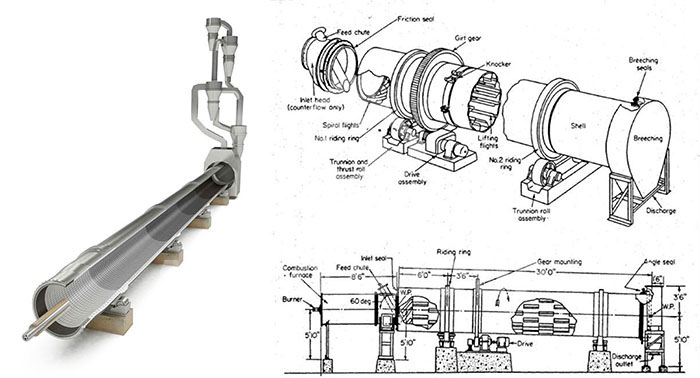

Cement Rotary Kiln Structure

Cement Rotary Kiln is mainly composed of kiln cylinder, transmission device, supporting device, retaining wheel device, kiln head sealing device, kiln tail sealing device, kiln head cover and the so on.

<

<

Performance characteristics:

- The cement rotary kiln adopts a new type of thermal insulation material to reduce the radiant heat loss and reduce the heat consumption;

- The new composite fish scale soft seal is used at the kiln tail to make the air leakage coefficient less than 10%, and at the same time meet the environmental protection requirements.

- The lime kiln adopts the kiln type with larger diameter and shorter kiln body, and adopts 2-speed support, which not only reduces the upper and lower turbulence amplitude of the kiln body, but also prolongs the cycle of the kiln ring, reduces the transmission force and reduces the energy Consumption.

Techincal Parameter of Rotary Kiln

|

Equipment Size mm |

Slope % | Production capacity (t/d) | Rotating Speed(r/min) | Motor Model |

Power (KW) |

Weight |

|---|---|---|---|---|---|---|

| Φ1.6*20 | 4 | 10 | 0.14-1.64 | AG JZT362-4 | 17 | 45.9 |

| Φ 1.8*18 | 4 | 12 | 0.08-1.04 | AG JZT371-4 | 22 | 51.2 |

| Φ1.9/1.6*36 | 4 | 72 | 0.3-1.76 | AG YCT280-4A | 30 | 62.9 |

| Φ2.5/2.2*50 | 3.5 | 96 | 0.5-1.55 | AG YCT315-4A | 55 | 154.9 |

| Φ2.8/2.5*55 | 3.5 | 132 | 0.5-1.55 | AG Z2-92 | 75 | 210 |

| Φ3/2.5*60 | 3.5 | 168 | 0.5-1.8 | AG ZSH4-225-11 | 75 | 429.5 |

| Φ3.0*48 | 3.5 | 840 | 0.43-3.62 | AG ZSH4-250-11B | 110 | 241 |

| Φ3.2*50 | 3.5 | 1200 | 0.36-3.57 | AG ZSH4-250-091B | 160 | 259 |

| Φ3.3*52 | 3.3 | 1320 | 0.398-3.975 | AG ZSH4-250-11B | 190 | 243 |

| Φ3.5*52 | 3.5 | 1500 | 0.36-3.51 | AG ZSH4-315-082 | 190 | 318 |

| Φ3.95*56 | 3.5 | 2000 | 0.6-3.3 | AG ZSN4-315-0T2' | 250 | 418 |

| Φ4*60 | 3.5 | 2500 | 0.396-3.96 | AG ZSH4-355-092 | 315 | 497 |

| Φ4.2*60 | 3.5 | 2800 | 0.4165-4.165 | AG ZSH4-355-12 | 420 | 576.1 |

| Φ4.3*62 | 3.5 | 3000 | 0.398-3.98 | AG ZSH4-355-12 | 420 | 598.5 |

| Φ4.8*74 | 3.5 | 5000 | 0.35-4 | AG ZSH4-400-092 | 630 | 841 |

Working Principle of Cement Rotary Kiln:

The cement rotary kiln is a cylindrical body with a certain inclination, and the inclination is 3 to 3.5%. The rotation of the kiln is used to promote the stirring of the material in the rotary kiln, and the materials are mixed and contacted for reaction. The combustion of the kiln head fuel produces a large amount of heat, and the heat is transmitted to the material by the radiation of the flame, the convection of the hot gas, and the conduction of the kiln brick (kiln skin). The material moves forward in the kiln by the inclination of the kiln cylinder and the rotation of the kiln.

The raw material is calcined from the high temperature of the kiln tail cylinder into the cylinder. Due to the inclination and slow rotation of the kiln, the material produces a composite motion that rolls both in the circumferential direction and from the high end to the lower end in the axial direction. The raw material is decomposed, burned and cooled in the kiln. After the mature material is burned, it is taken out from the low end of the kiln cylinder and enters the cooling machine. The fuel is injected from the kiln head, and is burned in the kiln. The heat is heated to heat the raw material, so that the raw material is calcined into clinker. The hot air formed during the heat exchange with the material enters the kiln tail system from the feed end of the kiln. Finally, it is discharged into the atmosphere by the chimney.