Cone Crusher Machine

Cone crusher is a newly developed hydraulic crusher with high power, large crushing ratio and high productivity. The machine was developed on the basis of digesting and absorbing various types of cone crushers with international advanced level in 1980s. It is clearly different in design from conventional cone crusher structure and concentrates on main advantages of various types of cone crushers. Cone crusher is suitable for fine crushing and ultra-fine crushing of hard rock, ore, slag, refractory materials, etc. It is widely used in dry cement production plant in raw material crusing process, especially for stage 2 and stage 3 crushing.

Application Fields of Cone Crusher:

Cone crusher is suitable for crushing of raw materials in the metallurgy, construction, road construction, chemical and silicate industries, and can break various ores and rocks of medium and medium hardness. It has large crushing ratio, high efficiency, low energy consumption and uniform product size. It is suitable for medium and fine crushed ores and rocks.

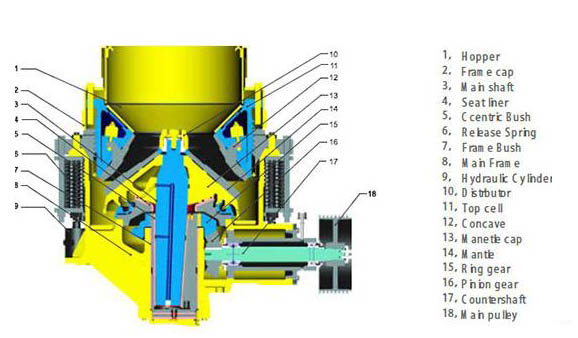

Cone Crusher Structure and Components:

The components of cone crusher mainly includes frame, horizontal axis, moving cone, balance wheel, eccentric sleeve, upper broken wall (fixed cone), lower broken wall (moving cone), hydraulic coupling, lubrication system, hydraulic system, The control system is composed of several parts.

Why Cone Crusher is Your Best Option:

(1) Hydraulic System, Which has a hydraulic system to adjust the size of the crushing material, and hydraulic system can effectively ensure safe operation of the equipment. When there is unwanted matter in the crushing chamber, hydraulic system can automatically lower the moving cone. When the unwanted matter is discharged, the system automatically resets falling moving cone. Re-maintain original discharge port position and continue to work;

(2) Crushing Cavity Type, Crushing cavity type refers to geometric space formed between moving cone and fixed cone. The shape of crushing chamber has a great influence on equipment performance. Crusher cavity type is main technical indicator of crushing. The machine is designed in four sizes from coarse to fine, and it has six possible combinations, which means it is best suited to user's specific requirements;

(3) Reliable Sealing: Labyrinth sealing device is used to replace water-type seal used in the past, so that dust and impurities can not enter human body, thus ensuring cleaning of lubricating oil and prolonging the service life of sliding bearing and thrust ball bearing. Ensures cone crusher running reliably;

(4) Convenient Replacement: In the past, it is comlicated to replaced broken linner of old type crusher, and linner can be replaced for new structure of cone crusher replaced very quickly. For the upper broken linner is equipped with a card tip, it is fixed by bolting up. The lower broken wall is fixed by hydraulic nut. The back and bottom of the broken linner do not need to add any filling material, so replacement is fast, and the reduction is reduced. Labor intensity of workers;

(5) Adjusting Discharge Port: It uses a high-pressure-resistant displacement sensor, and discharge port position is adjusted in the operation room. With one button press, there is a display on the console, and you can see the size of the drain port you need to adjust, which is very convenient and accurate.

Cone Crusher Models and Specification:

| Equipment | Model | Specification | Weight (t) | Design capability (t/h) |

|---|---|---|---|---|

| Cone crusher | Φ1200 | Standard | 25 | 110-168 |

| Medium | 24.8 | 42-135 | ||

| Short head | 25.5 | 18-105 | ||

| Cone crusher | Φ1750 | Standard | 50.3 | 280-480 |

| Medium | 50.3 | 115-320 | ||

| Short head | 50.3 | 75-230 | ||

| Cone crusher | Φ2200 | Standard | 79 | 59-1000 |

| Medium | 80.5 | 200-580 | ||

| Short head | 80.5 | 120-340 | ||

| Simmons cone crusher | 5.5YP.00D | Short head fine (1607) | 53.9 | 90-200 |

| Short head medium (1608) | 54.2 | 150-310 | ||

| Short head type (1613) | 53.8 | 210-370 | ||

| Short head thick (1614) | 53.7 | 253-336 | ||

| Simmons cone crusher | 5.5YP.00B | Standard fine type (1620) | 52.2 | 180-320 |

| Standard medium (1624) | 51 | 255-410 | ||

| Standard coarse type (1626) | 54.4 | 330-700 | ||

| Standard extra thick (1636) | 54.2 | 475-750 | ||

| Simmons cone crusher | AG PYS-DC | Short head (2110) | 101 | 320-500 |

| Short head medium (2113) | 100 | 380-650 | ||

| Short head type (2117) | 101 | 500-740 | ||

| Short head thick (2120) | 100.5 | 580-780 | ||

| Simmons cone crusher | AG PYS-BC | Standard extra thick (2146) | 102 | 1060-1600 |

| Standard coarse type (2136) | 103 | 900-1450 | ||

| Standard medium (2133) | 103 | 750-1200 | ||

| Standard fine type (2127) | 103.2 | 500-880 |

Cone Crusher Technical Performance:

| Equipment | Main Technical Performance | Transmission part | |

|---|---|---|---|

| Motor | |||

| Model | Power (kw) | ||

|

Cone crusher |

Feed ≤145 discharge size 20-50 | AG JS126-8 730r/min 220/380V | 110 |

| Feed ≤100 discharge size 8-25 | |||

| Feed ≤50 discharge size 3-15 | |||

|

Cone crusher |

Feed ≤215 discharge size 25-60 | AG JS128-8 735r/min 220/380V | 155 |

| Feed ≤185 Discharge size 10-30 | |||

| Feed ≤85 discharge size 5-15 | |||

|

Cone crusher |

Feed ≤310 discharge size 30-60 | AG JSQ158-12 490r/min 6000V | 260 |

| Feed ≤ 230 discharge size 10-30 | |||

| Feed ≤100 discharge size 5-15 | |||

|

Simmons cone crusher |

Feed port size: 70mm discharge opening adjustment range: 5-13mm |

AG JS136-6 | 240 |

|

Feed port size: 89mm discharge opening adjustment range: 6-19mm |

AG JS136-6 | 240 | |

|

Feed port size: 133mm discharge opening adjustment range: 10-16mm |

AG JS136-6 | 240 | |

|

Feed port size: 133mm discharge opening adjustment range: 13-19mm |

AG JS136-6 | 240 | |

|

Simmons cone crusher |

Feed port size: 210mm discharge opening adjustment range: 16-38mm |

AG JS136-6 | 240 |

|

Feeding port size: 240mm discharge opening adjustment range: 22-50mm |

AG JS136-6 | 240 | |

|

Feed port size: 269mm discharge opening adjustment range: 25-64mm |

AG YRKK4003-6 | 220 | |

|

Feed port size: 370mm discharge opening adjustment range: 38-64mm |

AG YRKK4003-6 | 250 | |

|

Simmons cone crusher |

Feeding port closed side size: 51mm feed port size: 105mm discharge opening adjustment range: 6-16mm |

AG Y450-46-6 | 400 |

|

Feeding port closed edge size: 95mm feed port size: 133mm discharge port adjustment range: 10-19mm |

AG Y450-46-6 | 400 | |

|

Feeding port closed side size: 127mm feed port size: 178mm discharge opening adjustment range: 13-25mm |

AG Y450-46-6 | 400 | |

|

Feeding port closed edge size: 152mm feed port size: 203mm discharge opening adjustment range: 16-25mm |

AG Y450-46-6 | 400 | |

|

Simmons cone crusher |

Feeding port closed edge size: 425mm feed port size: 460mm discharge opening adjustment range: 38-64mm |

AG Y450-46-6 | 400 |

|

Feeding port closed side size: 334mm feed port size: 369mm discharge opening adjustment range: 31-64mm |

AG Y450-46-6 | 400 | |

|

Feeding port closed edge size: 303mm feed port size: 334mm discharge opening adjustment range: 25-50mm |

AG Y450-46-6 | 400 | |

|

Feeding port closed edge size: 253mm feed port size: 278mm discharge opening adjustment range: 22-38mm |

AGY450-46-6 | 400 | |