Gyratory Crusher

Gyratory Crusher Introduction

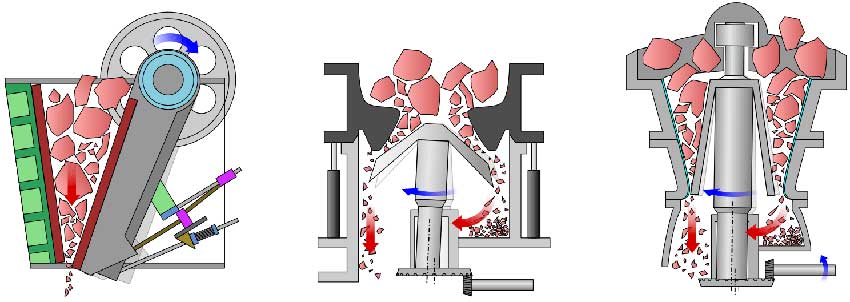

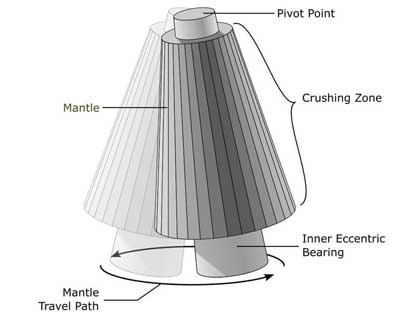

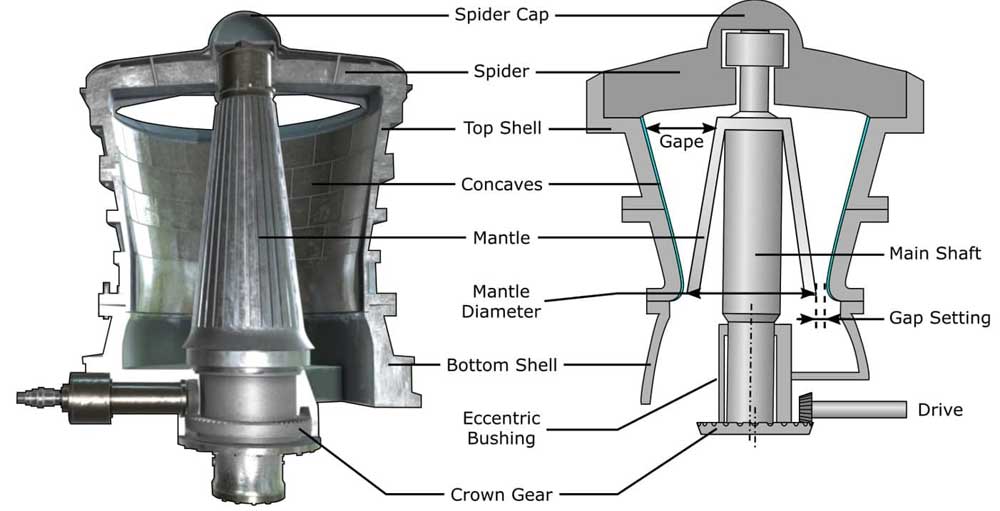

Gyratory crusher is a large-scale crushing machine that uses the gyratory motion of the crushing cone in the inner cone cavity of the shell to squeeze, split and bend the material, and roughly crush ores or rocks of various hardness. The upper end of the main shaft equipped with the crushing cone is supported in the bushing in the middle of the beam, and the lower end is placed in the eccentric hole of the bushing. When the shaft sleeve rotates, the crushing cone makes an eccentric gyratory movement around the center line of the machine. The crushing action is continuous, so the working efficiency is higher than that of the jaw crusher.

- Feed particle size: ≤ 1500mm

- Production capacity: 1120-6813t/h

- Application field: coarse crushing of various hardness ores or rocks

- Applicable materials: granite, basalt, diabase, andesite, etc.

Gyratory Crusher Specification

| Model | Inlet size (mm) | Discharge port adjustment range (mm) | Capacity(t/h) | Power(Kw) |

| AG810 | 1100 | 140-170 | 1120-1880 | 355 |

| AG830 | 1300 | 140-170 | 1560-2370 | 355 |

| AG1040 | 1400 | 160-210 | 2081-3015 | 450 |

| AG1050 | 1500 | 160-210 | 2350-3380 | 450 |

| AG1150 | 1500 | 175-220 | 3805-4930 | 800 |

| AG1450 | 1500 | 200-250 | 5315-6813 | 1100 |

Gyratory Crusher Feature

- High breakage rate Due to the high crushing rate, the particle size of the output product is smaller. This reduces pressure on conveyor transfer points, which reduces material handling costs, reduces downtime and reduces maintenance costs.

- Good product shape The special liner and crushing cavity structure can produce more valuable cubic block products and reduce the output of fine particles.

- Simple process The special design means that the crusher will not be oversaturated, simplifying the design of the production line and eliminating the need for transition stockpiles.

- low maintenance cost Spherical bearings are used, replacing the bushing design, eliminating point loading in this area - extending bearing life, reducing downtime and reducing maintenance costs.

- Large feed particle size Spherical bearings enable stronger eccentric movement in the crushing chamber, allowing for efficient crushing of very large feeds. Mine discharge port is adjustable Spherical bearings allow for smaller discharge openings, resulting in smaller product particle sizes at higher settings.

- Available for harder abrasive materials The heavy duty gyratory design is ideal for crushing harder abrasive materials like iron ore.