Air Box Pulse Dust Collector

Applications: Widely used in metallurgy, mining, power, building materials, machinery manufacturing, grain processing, chemical, boiler and other industries

Case:

The high-reliability design of air box pulse dust collector manufactured can adapt to the wide range of dust gas properties, high quality filter bags, programmable control system, low failure rate, and long-term stability of the dust collector. The dust leakage coefficient of the dust collector is <5%, which can meet extremely strict environmental protection requirements. The air box pulse dust collector provided for Ningxia customers and Inner Mongolia customers for collecting dust from pulverized coal station and collecting dust from finished products. The air box pulse dust collector provided for Huludao, Liaoning Province is used for dust collection at the kiln end of non-ferrous metal sintering rotary kiln. Customer feed backs are : the equipment is considered to be working well, the air leakage rate is low, the service life is long, and the flue gas outlet concentration reaches the standard.

Air Box Pulse Dust Collector Description:

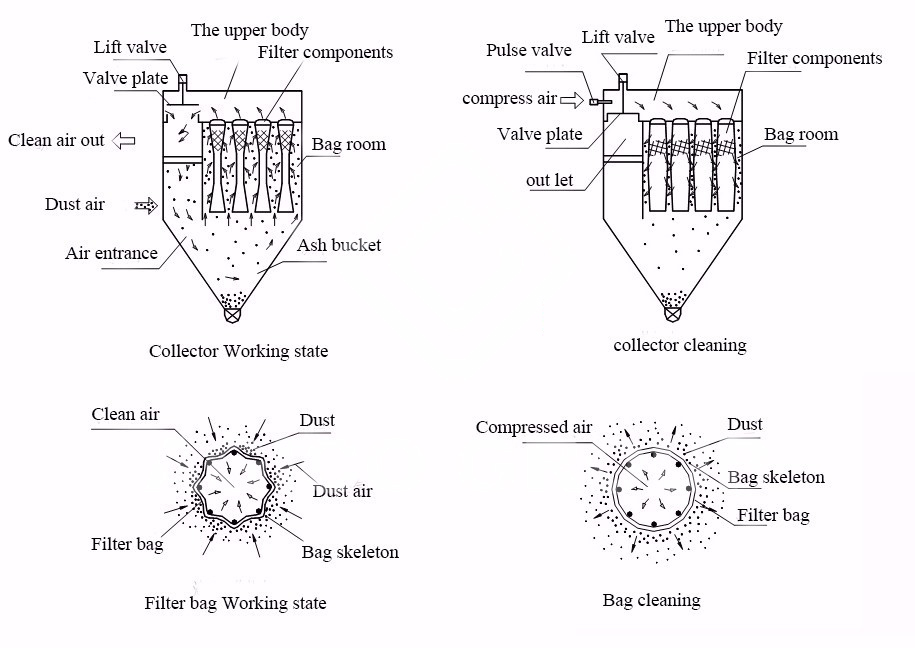

The air box type pulse bag dust collector is a high efficiency bag dust collector with advanced level. It overcomes the shortcomings of insufficient backflushing strength of the chamber, pulse jet cleaning and filtration. It combines the advantages of compartment backflushing and pulse jetting to clean all kinds of bag dust . Thereby expanding the application range of bag dust collector and improving the dust collection efficiency as well as extends the life of filter bag.

This series of dust collectors are outdoor type, which consists of different chambers and different pockets per room. There are 4 types of bags in each room: 32, 64, 96 and 128 bags. There are 33 specifications in the whole series. The diameter of the filter bag is φ130mm. The length of the filter bag is 2,450mm and 3060mm. This series of dust collectors can be operated under negative pressure or positive pressure without any change in the structure of the body. The dust collector inlet concentration of this series can reach up to 1000g/m3, and its dust collection efficiency can reach 99.9%. The main technical performance of this series which can be widely used in metallurgy, mining, electric power and building materials. , machinery manufacturing, food processing, chemicals, boilers and other industries.

With this series of dust collectors, there is no need to install a cyclone dust collector for primary dust collection. The filter material of this series of dust collectors generally adopts polyester needle felt, which allows the continuous use temperature to be less than 120oC. If the temperature of the treated exhaust gas is higher than the allowable temperature of the above filter material, aramid needle felt (Nomex) can be used. It allows a temperature of 210oC, but the filter material of this material is expensive. If the temperature of the treated exhaust gas is higher than the allowable temperature of the above filter material, the cooling measures should be taken before the exhaust gas enters the dust collector.

Suited Materials:

Technical Parameter of Air Box Pulse Dust Collector:

| Function requirement | PPC | PPC | PPC | PPC | PPC | PPC | PPC | PPC | PPC |

|---|---|---|---|---|---|---|---|---|---|

| S | S | S | S | S | S | S | S | S | |

| 32-3 | 32-4 | 32-5 | 32-6 | 64-4 | 64-5 | 64-6 | 64-7 | 64-8 | |

| Handling air volume ( m3/h ) | 6900 | 8930 | 11160 | 13390 | 17800 | 22300 | 26700 | 31200 | 35700 |

| Excess wind speed (m/min) | 0.8 ~ | 2.0 (Select different net filtering wind speeds according to different dust points) | |||||||

| Total over-exclusion area (m2) | 93 | 124 | 155 | 186 | 248 | 31 0 | 372 | 434 | 496 |

| Net filtration area (m2) | 62 | 93 | 124 | 155 | 186 | 248 | 31 O | 372 | 434 |

| Number of dust collectors (units) | 3 | 4 | 5 | 6 | 4 | 5 | 6 | 7 | 8 |

| The total number of filter bags (a) | 96 | 128 | 160 | 192 | 256 | 320 | 384 | 448 | 512 |

|

skills requirement |

PPC | PPC | PPC | PPC | PPC | PPC | PPC | PPC | PPC |

|---|---|---|---|---|---|---|---|---|---|

| S | S | S | S | S | S | S | S | S | |

| 32-3 | 32-4 | 32-5 | 32-6 | 64-4 | 64-5 | 64-6 | 64-7 | 64-8 | |

| Handling air volume ( m3/h ) | 6900 | 8930 | 1116 | 1339 | 1780 | 2230 | 2670 | 3120 | 3570 |

| Excess wind speed (m/min) | 0.8 ~ | 2.0 (Select different net filtering wind speeds according to different dust points) | |||||||

| Total over-exclusion area (m2) | 93 | 124 | 155 | 186 | 248 | 31 0 | 372 | 434 | 496 |

| Net filtration area (m2) | 62 | 93 | 124 | 155 | 186 | 248 | 31 O | 372 | 434 |

| Number of dust collectors (units) | 3 | 4 | 5 | 6 | 4 | 5 | + | 7 | 8 |

| The total number of filter bags (a) | 96 | 128 | 160 | 192 | 256 | 320 | 384 | 448 | 512 |

| parameter | Handling air volume (m3/h) | Filtration wind speed (m/min) | Filtration area (m2) | Number of filter bags (a) | Resistance (Pa) | Dust concentration (g/m3) | Insulation area (m2) | Weight (kg) | |

|---|---|---|---|---|---|---|---|---|---|

| model | |||||||||

| AG PPC32-3 | 6900 | 1.2-2.0 | 93 | 96 | 1470-1770 | <1000 | 26.5 | 2.880 | |

| AG PPC32-4 | 8930 | 124 | 128 | 34 | 4.080 | ||||

| AG PPC32-5 | 11160 | 155 | 160 | 41 | 5.280 | ||||

| AG PPC32-6 | 13390 | 186 | 192 | 48.5 | 6.480 | ||||

| AG PPC64-4 | 17800 | 248 | 256 | 70 | 7.280 | ||||

| AG PPC64-5 | 22300 | 310 | 320 | 94 | 9.960 | ||||

| AG PPC64-6 | 26700 | 372 | 384 | 118 | 11.640 | ||||

| AG PPC64-7 | 31200 | 434 | 448 | 142 | 13.320 | ||||

| AG PPC64-8 | 35700 | 496 | 512 | 166 | 15.000 | ||||

| AG PPC96-4 | 26800 | 372 | 384 | <1300 | 110 | 10452 | |||

| AG PPC96-5 | 33400 | 465 | 480 | 120 | 12120 | ||||

| AG PPC96-6 | 40100 | 557 | 576 | 130 | 14880 | ||||

| AG PPC96-7 | 46800 | 650 | 672 | 140 | 16920 | ||||

| AG PPC96-8 | 53510 | 744 | 768 | 150 | 19810 | ||||

| AG PPC96-9 | 60100 | 836 | 864 | 160 | 21240 | ||||

| AG 96-2×5 | 66900 | 929 | 960 | 175 | 25200 | ||||

| AG 96-2×6 | 80700 | 1121 | 1152 | 210 | 30240 | ||||

| AG 96-2×7 | 94100 | 1308 | 1344 | 245 | 35280 | ||||

| AG 96-2×8 | 107600 | 1494 | 1536 | 280 | 40320 | ||||

| AG 96-2×9 | 121000 | 1681 | 1728 | 315 | 45360 | ||||

| AG 96-2×10 | 134500 | 1868 | 1920 | 350 | 50400 | ||||

| AG 128-6 | 67300 | 935 | 768 | 125 | 24120 | ||||

| AG 128-9 | 100900 | 1402 | 1152 | 196 | 31680 | ||||

| AG 128-10 | 112100 | 1558 | 1280 | 205 | 34680 | ||||

| AG 128-2×6 | 34600 | 1869 | 1536 | 323 | 43920 | ||||

| AG 128-2×7 | 15700 | 2181 | 1792 | 247 | 52680 | ||||

| AG 128-2×8 | 179400 | 2492 | 2084 | 262 | 60000 | ||||

| AG 128-2×9 | 201900 | 2804 | 2304 | 277 | 66480 | ||||

| AG 128-2×10 | 224300 | 3115 | 2561 | 292 | 72000 | ||||

| AG 128-2×11 | 247600 | 3427 | 2856 | 307 | 78480 | ||||

| AG 128-2×12 | 269100 | 3728 | 3072 | 322 | 96400 | ||||

| AG 128-2×13 | 291600 | 4050 | 3328 | 337 | 93600 | ||||

| AG 128-2×14 | 314000 | 4361 | 3584 | 252 | 100800 | ||||

Air Box Pulse Dust Collector Structure and Working Principle:

The composition includes a clean air chamber, a filter chamber, a bracket, a filtering device, a blowing device, an ash discharging device, and an ash conveying device.

Performance characteristics:

- Adopt world-class high-quality components to improve equipment operation reliability and reduce maintenance work;

- All high-quality filter bags and accessories are used. The average life of filter bags is generally about two years;

- The filter bag skeleton is made of cold drawn steel wire and galvanized. It has excellent rigidity, strength, manufacturing precision and durability, and reduces the wear on the filter bag. The service life of the skeleton can reach more than 5 years.

- Complete serial design to meet the dust control needs of a variety of dust sources;

- Standardized design to reduce the storage of spare parts for users.

The dust collection technology of Gas Box Pulse Dust Collector is very mature, with high reliability and excellent performance and price ratio.