Activated Carbon Rotary Kiln

What is Rotary Kiln for Activated Carbon Plant

Activated carbon rotary kiln belongs to calcination equipment, it is used to process activated carbon to improve utilization rate of activated carbon, and production of non-metallic minerals with high carbon content, through redox reaction, the carbon-containing raw materials are decomposed, and high-purity activated carbon is obtained. This equipment is mainly composed of cylinder, kiln hood, power device, combustion device, support device and other components, cylinder is the burning room of the activated carbon rotary kiln, made of high-quality steel coil welding, the support device is equipped with hydraulic retaining wheels, which can avoid axial channeling of the cylinder during operation, and guarantee the production process is more stable and safe.

Activated Carbon Rotary Kiln Specification:

| Product Standard(m) | Kiln Size | Length(m) | Inclination(%) | Yield(t/d) | Rotate Speed(r/min) | Motor Power(kW) | Gross Weight(t) | Remarks |

|---|---|---|---|---|---|---|---|---|

| Diameter(m) | ||||||||

| Φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149.61 | |

| Φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187.37 | Decomposition kiln outside kiln |

| Φ2.5×54 | 2.5 | 54 | 3.5 | 280 | 0.48-1.45 | 55 | 196.29 | |

| Φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 198.5 | Decomposition kiln outside the kiln |

| Φ2.8×44 | 2.8 | 44 | 3.5 | 450 | 0.437-2.18 | 55 | 201.58 | |

| Φ3.0×45 | 3 | 45 | 4 | 500 | 0.5-2.47 | 75 | 201.94 | Decomposition kiln outside the kiln |

Rotary Kiln for Activated Carbon Production

Activated carbon, also known as activated charcoal, is a material with a high carbon content, often in the form of granules or powders, with strong adsorption, stable chemical properties and other characteristics. It has a strong adsorption capacity, is often used as an adsorbent in various industries .The origin of activated carbon is the organic materials with high carbon content, such as coal, wood, etc. obtained by high temperature action in furnance. in the whole production process of activated carbon, the core equipment is activated carbon rotary kiln, which provide high temperature condition for the physical and chemical reactions in cabonization process.

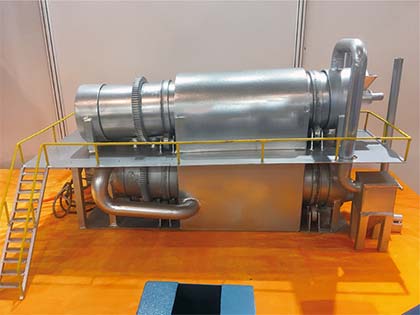

What is Activated carbon rotary kiln structure

Activated carbon rotary kiln was a mining machinery, after years of intensive research by AGICO it has nown been developed with many patents, technology and quality assurance. The rotary kiln is mainly composed of rotary body, lifting plate, transmission device, support device and sealing ring and other components, the whole machine structure is reasonable, well-made, the equipment has high output, low energy consumption, convenient operation and other advantages. The materials produced by the activated carbon rotary kiln have the advantages of strong chemical reaction ability, small bulk density and large specific surface area, and are currently one of the main auxiliary materials in steelmaking, coking, calcium carbide and other industries at home and abroad.

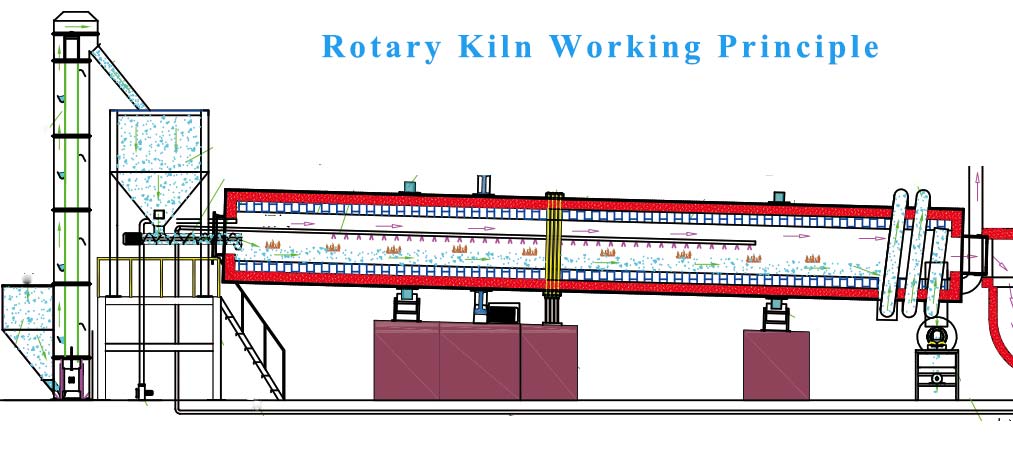

Activated Carbon Rotary Kiln Working Principle

Activated carbon rotary kiln is the main equipmnet in activated carbon production, High quality carbon raw material stored in silo, after it get lifted and transported into the preheater top, which controls the feeding amount with a couple of level gauges. Then the carbon raw material get distributed evenly to preheater chamber, decomposed by 30 percent, it get into activated carbon rotary kiln with the help of hydraulic pusher, the part of the carbon material is decomposed into CaO and CO2 in the sintering process in activated carbon rotary kiln.the activated carbon generated get into the cooler, after it's temperature is lowered to 100 ° C,the heat exchange will get mixed with gas for combustion in the kiln. Bag dust collector collects exhaust gas and let it out through exhaust fan.

Sucessful Cases of Activated Carbon Plant Equipments

| 2015 | Internal heat rotary furnace | Xinjiang Hami Project |

|---|---|---|

| 2015 | Activated carbon carbonization equipment | Thailand Project |

| Activated carbon activation equipment | ||

| 2016 | Activated carbon carbonization equipment, activation equipment, crushing and screening equipment | Yunnan Project |

| 2016 | Activated carbon carbonization equipment, activation equipment, crushing and screening equipment | Yunnan Project |

| 2016 | External heat type biomass pyrolysis rotary furnace, biomass pyrolysis activation furnace, combustion heating furnace and control system | Hainan Project |

| 2016 | Activated carbon equipment production line, drying equipment | Sri Lanka Project |

| 2016 | Activated carbon live furnace equipment | |

| 2016 | Crushing and screening equipment | |

| 2016 | Activated carbon detection experimental instrument | |

| 2017 | External heating carbonization equipment | Hubei Project |

| 2017 | Activated carbon activation equipment, crushing and screening equipment | Thailand Project |

| 2017 | Drying equipment | Trading Company |

| Crushing and screening production line | ||

| 2018 | Activated carbon regeneration plant production line | Russian project |

| 2018 | Activated carbon activation line | Trading Company |

| 2018 | Activated carbon activation equipment | Indonesia project |

| 2018 | Carbon cooler | Trading Company |

| Screw conveyor |

Activated Carbon Rotary Kiln Advantages

- Environmental protection, energy saving, mechanization and high degree of automation (PLC bus control);

- AGICO rotary kiln adopts new burner technology, can make full use of cheap energy, especially the use of the original environmental pollution, a large number of outgoing combustible gases as part of the energy, so that it becomes waste into treasure.

- The raw materials and fuels of activated carbon rotary kiln production line are highly adaptable, simple maintenance, low energy consumption and other advantages are regarded as ideal kiln types by the industry.

Rotary Kiln for Carbonization:

Rotary Kiln is also used in the progress of carbonization of biomass materials, there are basically 2 types of rotary kiln: indirect heated rotary kiln and direct heated rotary kiln.

Indirect Rotary Kiln

Indirect rotary kiln is also called indirect fired rotary kiln, it works by creating a low temperature environment for destructive distillation process, raw material is heated slowly to form enough fixed carbon in cage structure though an ordered pyrolysis of plastic mass in them, to prepare for activation process.

Direct Heated Rotary Kiln

Direct Heated Rotary Kiln, or direct fired rotary kiln, is a common type of rotary kiln being widely used in many industries, it works by heating the raw materials with small amount of air to reduce the none carbon substances to a certain percent for activated carbon product, then it will be well prepared for the process of carbon activation.

Why choose Agico Activated Carbon Rotary Kiln

The activated carbon rotary kiln produced by AGICO is a kind of equipment with stable and efficient production of activated carbon, we owns many patents and technology certificates in activated carbon plant industry, it adopts a cooling system, activated carbon product is directly packaged after it is rapidly cooled, the whole machine is continuously mechanized, reducing the input of personnel, it is a rotary kiln equipment with large output and good quality, after activated process, different materials (coconut shell, fruit shell, wood, bio-coal,) can be tested on the spot of the finished activated carbon, so that the finished product reaches the maximum adsorption capacity, and the sales prospect is very optimistic.

High handling temperature

The temperature in the activated carbon rotary kiln is between 950 degrees and 1050 degrees, and in the state of high temperature, the impurities in the material can be decomposed, and the calcination process is mature, and the product quality is high.

Large Impact

The impact of the equipment is large, which can clean the ring in the kiln in a relatively short period of time, reduce the occurrence of the ring phenomenon, and reduce the heat transfer efficiency.

Environment-Friendly Production

Activated carbon rotary kiln adopts the new burner technology, the fuel adaptability is strong, customer can choose various type of fuels.

High efficiency of Heat

Rotary kiln cylinder is designed with reasonable structure, high heat transfer efficiency, easy control of heating temperature.