Electric Precipitator

- Applications: Widely used in non-ferrous metals, metallurgy, electric power, building materials, coal, petroleum and chemical industries.

- Materials: Used in coal-fired factories and power stations to collect coal ash and dust from flue gas. Metallurgy is used to collect oxides of tin, zinc, lead, aluminum, etc., and there are also dust sterilization products that can be used in households.

Case:

The electric precipitator supplied by AGICO has low resistance, low energy consumption, high temperature resistance and dust collection efficiency greater than 99%. Electric precipitator can increase the electric field cross-sectional area by up to 400m2 by increasing the electric field length. AGICO has provided 2 120m2 electric precipitators for Ningxia customers for kiln tail dust collection of 600t/d active lime production line for 5 years. The customer reports that equipment is working well, dust removal effect is high, and the service life of the accessories is long.

Electric Precipitator Description:

Electrostatic dust removal is one of the methods of gas dedusting. The dust-containing gas is electrically separated when passing through a high-voltage electrostatic field, and after the negative combination of the dust particles and the negative ions, the surface of anode is discharged and deposited. This equipment is used in the metallurgical, chemical and other industries to purify gases or recover useful dust particles. Working method in which a gas is ionized by an electrostatic field to electrically adsorb dust particles to an electrode.

In a strong electric field, air molecules are ionized into positive ions and electrons, and electrons encounter dust particles during the process of the positive electrode, so that the dust particles are negatively charged and absorbed to the positive electrode to be collected. Of course, through technological innovation, there is also a way of collecting dust using a negative plate. In the past, it was often used in coal-fired factories and power stations to collect coal ash and dust from flue gas.

Technical Parameter of Electric Precipitator:

| Electric precipitator technical parameters | |||||

| Mode | AG HEP6C | AG HEP90 | AG HEP120 | AG HEP175 | AG HEP185x2 |

| Gas Handling Capacity (Nm3/h) | 16000C | 210000 | 302400 | 441000 | 466200 |

| mMmm ( m/s ) | 0.65 | 0.65 | 0.7 | 0.7 | 0.7 |

| Dust Concentration at Inlet (mg/ m3) | <80 | ||||

| Dust Concentration at Outlet (mg/m3) | <100 | <100 | <100 | <100 | <50 |

| Chamber number/ electric field | 3/3 | 3/3 | 3/3 | 3/13 | 4/8 |

| Homopolar spacing (mm) | 400 | ||||

| Number of channels | 21 | 24 | 24 | 28 | 36 |

| Inlet flue gas temperature °C | <300 | <300 | <300 | <300 | <300 |

| Rapping type | mechanical | mechanical | mechanical | mechanical | mechanical |

| Rectifier transformer specification model (A/KV) | GGAJO2-0.5A/72KV | GGAJO2-0.8A/72KV | GGAJO2-1.0A/72KV | GGAJO2-1.0A/72KV | GGAJO2-1.0A/72KV |

-

High dust removal efficiency

Electrostatic precipitator can improve dust removal efficiency by lengthening the length of the electric field, increasing the cross-sectional area of the electric field, improving the quality of the power supply, and quenching the flue gas. For the conventional electrostatic precipitator, the dust removal efficiency is more than 99% in normal operation, which is a very common phenomenon. For fine dust with a particle size of less than 0.1 μm, the electrostatic precipitator still has a high dust removal efficiency. -

Low resistance and low energy consumption

The total energy consumption of electrostatic precipitator is composed of energy losses such as equipment pressure loss, power supply, heating, rapping and ash discharging motors. The pressure loss of electrostatic precipitator is generally 150-300 Pa, which is about 1/5 of bag filter, and energy consumption is low. -

Handling large amount of smoke

Since the electrostatic precipitator is structurally easy to modularize, it is possible to enlarge the apparatus. At present, the maximum electric field cross-sectional area of a single electrostatic precipitator exceeds 400m2, and the amount of treated flue gas can reach 2 million m3/h. -

High temperature resistance, capable of trapping highly corrosive aerosol particles

Conventional electrostatic precipitators are used to treat flue gases up to and including 350 degrees Celsius. If specially designed, they can handle flue gases above 500 degrees Celsius. For aerosol particles such as sulfuric acid mist and asphalt fog, which are highly corrosive and highly adherent, a wet electrostatic precipitator can maintain good trapping performance. -

High requirements for manufacturing, installation and operation levels

Because the electrostatic precipitator has a complicated structure and a large volume, it has strict requirements on manufacturing quality, installation accuracy and operation level, otherwise the expected dust removal effect cannot be achieved. -

Vulnerable to working conditions

Although the electrostatic precipitator has a wide adaptability to flue gas properties and dust characteristics, when the operating parameters deviate from the design values, performance of the electrostatic precipitator will change accordingly. It is most sensitive to the dust specific resistance. When dust is too high or too low, the dust removal efficiency will be reduced.

Working Principle of Electric Precipitator:

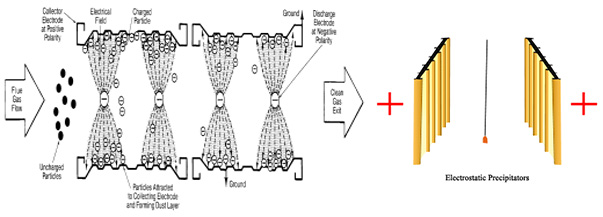

The electrostatic precipitator uses a high-voltage direct current electric field to ionize gas molecules in the air, generates a large amount of electrons and ions, moves to the two poles under the action of the electric field force, and encounters the dust particles and bacteria in the airflow to make them charge during the moving process. The electric particles move to the opposite electrode plate under the action of the electric field force. Under the action of the electric field, the free ions in the air move toward the two poles.

The higher the voltage, the higher the electric field strength, and the faster the ion movement speed. Due to the movement of the ions, a current is formed between the poles. At the beginning, there are fewer free ions in the air and less current. After the voltage rises to a certain value, the ions near the discharge electrode get higher energy and speed. When they hit the neutral atoms in the air, the neutral atoms will decompose into positive and negative ions. This phenomenon is called air ionization. After air ionization, due to the chain reaction, the number of ions moving between the poles is greatly increased, and the current between the poles (called the corona current) is sharply increased, the air becomes a conductor, and the high-intensity voltage captures the accompanying bacterial particles, and the instantaneous conductive strike Wear the cell wall composed of protein to achieve the elimination of bacteria adsorption and dust removal.