Burried Scraper Chain Conveyor

- Application: Buried scraper conveyor for metallurgy, machinery, light industry, food, transportation and other departments

- Materials: Dust-like materials such as dust, small particles and blocks, and various food crops

- Buried Scraper Conveyor Types: MS16, MS20, MS25, MS32, MS40, MS50

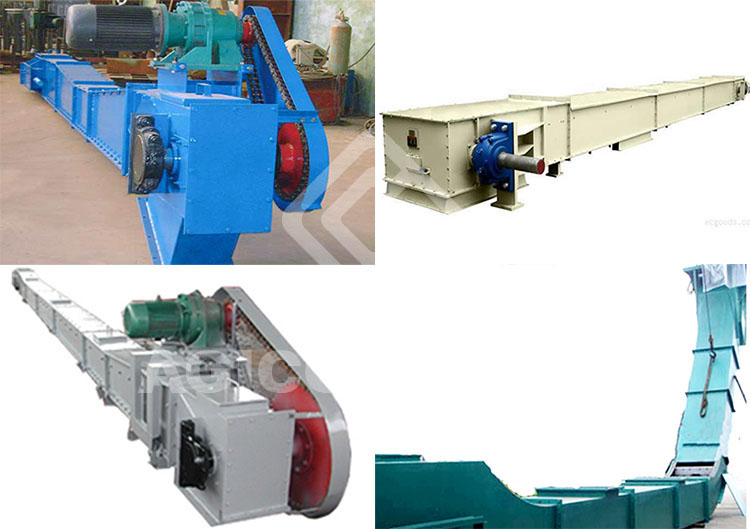

Case:

The buried scraper conveyor for Henan customers is used to transport cement products in cement plants. The customer feedback is equipment structure is reasonable, and it can be fed more than before. The moving speed of the scraper is stable under the transmission of the planetary cycloid reducer, it runs with low noise.

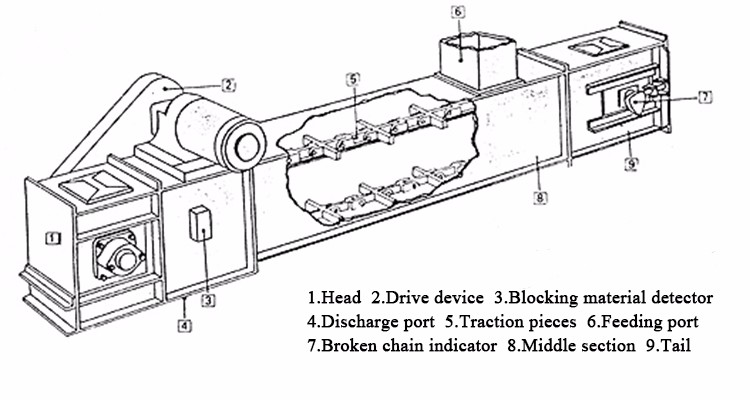

Buried Scraper Conveyor Description:

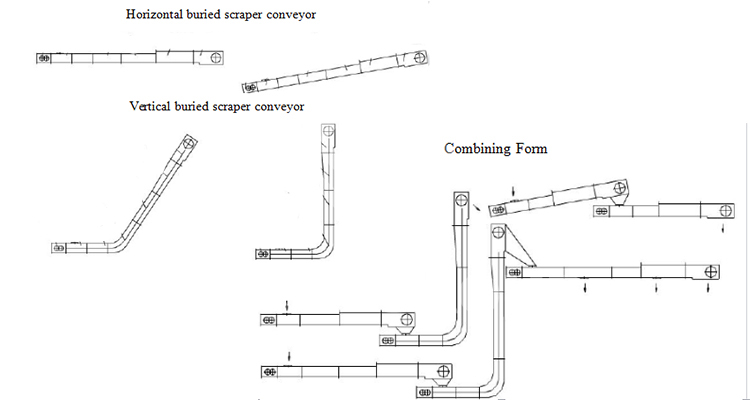

Buried scraper conveyor is used in the departments of metallurgy, machinery, light industry, food, transportation and so on. Models are: general-purpose, hot-type, soda-only (common, high-efficiency), grain-specific, cement-specific, power plant-specific, etc., with a groove width of 120-1000mm. The scraper conveyor is a continuous conveying device that transports bulk materials such as dust, small particles and blocks, and can be transported horizontally, obliquely and vertically. The bulk material has characteristics such as internal friction and side pressure. When conveying horizontally, raw material is subjected to thrust of scraper chain in the moving direction.

When the internal friction between material layers is greater than external friction between material and groove wall, material moves forward with scraper chain. When transporting vertically, it mainly depends on the arching characteristics of the material. The buried scraper conveyor is mainly composed of a closed section housing (machine slot), a scraper chain, a driving device and a tensioning device. The utility model has the advantages of simple structure, small volume, good sealing performance, convenient installation and maintenance, multi-point feeding, multi-point discharging, flexible process selection and arrangement; Can improve working conditions and reduce environmental pollution when conveying flying, toxic, high temperature, flammable and explosive materials.

Technical Parameter of Buried Scraper Conveyor:

| Technology data of buried scraper conveyor | ||||||

|---|---|---|---|---|---|---|

| Project Model | AG MS16 | AG MS20 | AG MS25 | AG MS32 | AG MS40 | AG MS50 |

| Material bulk density(t/m3) | 0.2-1.8 | 0.2-1.8 | 0.2-1.8 | 0.2-1.8 | 0.2-1.8 | 0.2-1.8 |

| Capacity(m3/h) | 15~30 | 23~46 | 36~72 | 59~118 | 83~166 | 115~230 |

| Max distance(m) | 40 | 40 | 40 | 40 | 60 | 60 |

| Safe inclined | 0-15° | 0-15° | 0-15° | 0-15° | 0-15° | 0-15° |

| Chain pitch(mm) | 100 | 125 | 160 | 200 | 200 | 250 |

Performance characteristics:

- Since the buried scraper conveyor moves with the animal material by the internal friction of the material, the running resistance is small and the energy consumption is low, energy saving is about 50% compared with the screw conveyor;

- The conveyor chain adopts the sleeve roller plate chain structure made of high-strength wear-resistant alloy, and is processed by special process, featuring high strength, small friction coefficient and long service life;

- Wide range of transportation, it can carry out various powdery, granular and block materials with large capacity and long distance conveying temperature below 150 °C;

- The whole conveying process is carried out in a confined space, the sealing is safe and reliable, and especially suitable for conveying special media such as volatile, toxic and corrosive;

- Flexible process layout, it can be arranged horizontally or obliquely, and can be fed or unloaded at multiple points to facilitate connection with other equipment;

- The whole machine has compact structure, small occupied space, less wearing parts, and convenient operation and maintenance;

Working Principle of Buried Scraper Conveyor:

The working principle of buried scraper conveyor is that transmission drives the drive sprocket to rotate, conveyor chain with the scraper meshes with drive sprocket and moves accordingly; when the material is added from feed inlet, it is received in slot, then pulling force of conveyor chain moves in the same direction, so that the internal friction and internal pressure between raw materials increases. When the friction is greater than friction between the material and the groove wall, it is driven forward by the conveyor chain movement, and increased internal pressure ensures a stable state between the layers, creating a continuous flow. When the ratio of the layer height meets certain conditions, transmission flow is stable and the material speed is about equal to chain speed, so material is continuously and stably transported from discharge port.