Ball Mill

- Applications: Mainly used in grinding operations in mining, cement, refractory, chemical and other industries.

- Materials: Mine ball mills are divided into dry and wet, dry type for refractory materials, cement, fertilizer, glass industry; wet type for mineral processing, ceramics, chemical industry.

- Ball Mill Types: MQ series, MQS series, MQY series

Cement Ball Mill Description:

MQ series ball mills are mainly used in grinding operations in mining, cement, refractory, chemical and other industries. According to the discharging method, it is divided into MQG series dry type lattice ball mill, MQS series wet type lattice ball mill, MQY series wet overflow type ball mill, MQZ series peripheral discharge type ball mill; according to the type of liner, it is divided into A series (high manganese steel lining). Plate, magnetic lining) standard type and B series (rubber lining, high aluminum lining, silica lining, ceramic lining) energy-saving type; according to the transmission mode is divided into edge drive ball mill and center drive ball mill.

Technical Parameter of Cement Ball Mill:

| Main technical parameters of cement ball mill | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Specification | Production (t/h) |

Speed (r/min) |

Abrasive body (t) | Electric Motor | Reducer |

Weight (t) |

Dimensions (m) | ||

| Model one | Power (KW) | Model | Power (KW> | ||||||

| Φ3 * 9 | 33-34 circle | 19.6 | 79 |

YR1000-8 / 1180 / Y 160M-4 |

1000/11 | NAL108/8/ZS110-19 | 8/280 | 156.5 | 25.2*6.6*5.8 |

| Φ3 * 11 | 35-40 laps | 18.3 | 97 |

YR1250-8 / 1430 / Y 160M-4 |

1250/11 | YNL1210 | 6.3 | 178 | 26.4*5.8*5.8 |

| Φ3 * 12 | 38-40 closed circuit | 18.1 | 100 |

YR1250-8 / 1430 / Y 160M-4 |

1250/11 | JSllO | 41.27 | 187.3 | 27.2*5.9*4.8 |

| Φ3.2 * 11 | 40 closed circuit | 18 | 103 |

YR1400-8 / 1430 / Y 160M-4 |

1450/11 | YNL1210 / ZS110-19 | 12.35/28 | 186.1 | 26.4*6.5*6.1 |

| Φ3.5 * 11.5 | 50 closed circuit | 17.2 | 126 |

YR1800-8 / 1430 / Y 200L2-2 |

1800/37 | JSX1300A/JMX560 | 43.02/318 | 252.3 | 28*8*6.3 |

| Φ3.8*13 double track | 70-75 closed circuit | 16.6 | 186 | YRKK800-8 | 2500 | JS130 | 44.9 | 221.5 | 19.7*6.5*5.9 |

| Φ4 * 13 | 65 closed circuit | 15.95 | 202 | YRKK900-8 | 2800 | JS130 | 46.7 | ||

| Φ4.2 * 13 | 8 closed circuit | 16.3 | 224 | YRKK900-8 | 3150 | MFY320 | 47 | ||

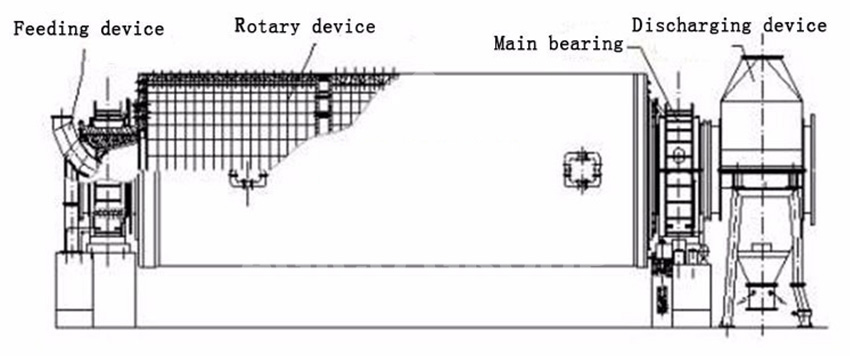

Cement Ball Mill Structure

When Ball Mill is working, raw material enters the mill cylinder through the hollow shaft of the feed. The inside of the cylinder is filled with grinding media of various diameters (steel balls, steel segments, etc.); when the cylinder rotates around the horizontal axis at a certain speed, Under the action of centrifugal force and friction force, the medium and the raw material in the cylinder will drop or roll off the inner wall of the cylinder when the gravity of the cylinder reaches a certain height.

When material particle gravity is greater than centrifugal force, they will be crushed due to the impact force. At the same time, during the operation of the mill, the sliding movement of the grinding media to each other also produces a grinding effect on the raw materials. The rest material is discharged through a discharge hollow shaft. Due to the constant uniform feeding, the pressure causes the material in the cylinder to move from the feed end to the discharge end. During wet grinding, the material is carried away by the water flow; during dry grinding, the material is taken away by the airflow drawn out of the cylinder.

Suited Materials:

Performance characteristics

- Reliable operation, continuous operation, large production capacity.

- Less transmission parts and low maintenance costs.

- The use of rolling bearings in the mining mill greatly reduces the running cost and maintenance cost and improves the operating rate.

Working Principle of Cement Ball Mill:

When Ball Mill is running, the raw material enters the mill cylinder through the hollow shaft of the feed. The inside of the cylinder is filled with grinding media of various diameters (steel balls, steel segments, etc.); when the cylinder rotates around the horizontal axis at a certain speed, Under the action of centrifugal force and friction force, raw material in the cylinder will drop or roll off the inner wall of the cylinder when the gravity of the cylinder reaches a certain height. When their own gravity is greater than the centrifugal force, they will be crushed due to the impact force. ore. At the same time, during the operation of the mill, the sliding movement of the grinding media to each other also produces a grinding effect on the raw materials. The ground material is discharged through a discharge hollow shaft. Due to the constant uniform feeding, pressure will causes the material in the cylinder to move from feed end to discharge end. During wet grinding, material is carried away by water flow; during dry grinding, raw material is taken away by the airflow drawn out of cylinder.