Belt Conveyor

- Applications: Widely used in docks, coal mines, metallurgy, food, paper and other industries

- Materials: Bulk materials widely used in coal, metallurgy, construction, food, chemical, electric power and other sectors

- Belt Conveyor Models: TD75, DTII belt conveyors

Case:

The belt conveyor is mainly used for long-distance transportation of powder and small block materials. High quality belt conveyor runs smoothly, no slip or run off, belt and roller have long service life, the upper belt type does not exceed the edge of drum or idler, and lower belt type does not grind the frame. Belt conveyor can be installed on the ground or installed in a high place or in a belt corridor with a tilt angle of 0 --- 18 degrees. A wide range of industries are available for this conveying equipment. Belt conveyors provided by AGICO to Ningxia and Inner Mongolia are mainly used for conveying materials in the active lime production line. Belt conveyors supplied to Shanxi are used for conveying raw materials in the white cement factory; Belt conveyors supplied to Pingxiang are used in the cementing plant loading system. Liaoning for the ceramsite production line to transport materials.

Belt Conveyor Description:

Belt conveyors are divided into TD Belt Conveyors and DTII Belt Conveyors. Belt conveyors have been widely used as continuous transportation machinery in docks, coal mines, metallurgy, grain, paper and other industries. It have low power consumption. Since the material and conveyor belt have almost no relative movement, not only the running resistance is small (about 1/3 to 1/5 of the scraper conveyor), but also the wear and breakage of the load are small, which means high productivity. These are all beneficial to reduce production costs. The lifting angle of ordinary belt conveyor is generally not 20°. The reason is that when the inclination of belt conveyor is greater than 20°, the material will fall for most materials, means the friction of the material on the belt is too small.

The conveyor line of the belt conveyor is adaptable and flexible. The length of the line is as needed. It is a few meters long and can be as long as 10km or more. It can be installed in small tunnels or over the ground in traffic chaos and dangerous areas.

Performance characteristics:

- The conveying distance is long and the length can exceed 1 km;

- Simple structure, convenient maintenance and low cost;

- Wide application range and large transportation volume;

- Smooth operation and low noise;

- Since there is no excavation resistance during charging and internal friction and external friction of the material during operation, the energy consumption is small;

Working Principle of Belt Conveyor:

The belt conveyor is mainly composed of frame, conveyor belt, belt roller, tensioning device, transmission device. The fuselage is made of high-quality steel plates, and frame is formed by the height difference of the front and rear legs, and the plane is inclined at a certain angle. A belt roller, a roller, etc. are mounted on the frame for driving and supporting the conveyor belt. There are two modes of geared motor drive and electric drum drive.

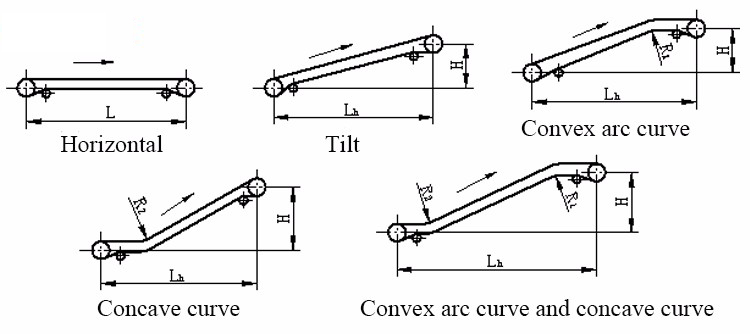

The belt moves according to the principle of friction transmission. According to the requirements of the conveying process, it can be transported by a single machine, or composed of multiple belt conveyors or with other conveying equipment to form a horizontal or inclined conveying system to meet the operation of different Line layout needs.

Technical Parameter of Belt Conveyor

| TD 75 Belt Conveyor | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Specification | Belt Width | Max Materials | Speed | Capacity (t/h) | Standard Weight(t) | 1m | ||||||||||

| (mm) | size(mm) | (m/s) | Weight increases | |||||||||||||

| screened/raw | flat | trough | 5m | 10m | 15m | 20m | 25m | 30m | 40m | 50m | 75m | 100m | with length (kg) | |||

| TD75 | B500 | 100/150 | 0.8 | 41 | 78 | 1.45 | 1.72 | 2.05 | 2.32 | 2.67 | 2.94 | 3.58 | 4.24 | 5.76 | 7.32 | 53 |

| 1 | 52 | 97 | ||||||||||||||

| 1.25 | 66 | 122 | ||||||||||||||

| 1.6 | 84 | 156 | ||||||||||||||

| 2 | 103 | 191 | ||||||||||||||

| 2.5 | 125 | 232 | ||||||||||||||

| TD75 | B650 | 130/200 | 0.8 | 67 | 131 | 1.78 | 2.1 | 2.48 | 2.79 | 3.19 | 3.5 | 4.24 | 5 | 6.75 | 8.5 | 62 |

| 1 | 88 | 164 | ||||||||||||||

| 1.25 | 110 | 206 | ||||||||||||||

| 1.6 | 142 | 264 | ||||||||||||||

| 2 | 174 | 323 | ||||||||||||||

| 2.5 | 211 | 391 | ||||||||||||||

| TD75 | B800 | 180/300 | 0.8 | 118 | 2.46 | 2.83 | 3.3 | 3.67 | 4.15 | 4.52 | 5.4 | 6.32 | 8.4 | 10.5 | 73 | |

| 1 | 147 | 278 | ||||||||||||||

| 1.25 | 184 | 348 | ||||||||||||||

| 1.6 | 236 | 445 | ||||||||||||||

| 2 | 289 | 546 | ||||||||||||||

| 2.5 | 350 | 661 | ||||||||||||||

| 3.15 | 824 | |||||||||||||||

| TD75 | B1000 | 250/400 | 1 | 230 | 435 | 3.52 | 4.1 | 4.82 | 5.4 | 6.15 | 6.72 | 8.1 | 9.25 | 12.1 | 15 | 116 |

| 1.25 | 288 | 544 | ||||||||||||||

| 1.6 | 368 | 696 | ||||||||||||||

| 2 | 451 | 853 | ||||||||||||||

| 2.5 | 546 | 1033 | ||||||||||||||

| 3.15 | 1233 | |||||||||||||||

| TD75 | B1200 | 300/500 | 1 | 345 | 655 | 4.25 | 4.94 | 5.8 | 6.49 | 7.4 | 8.09 | 9.74 | 11.4 | 15.3 | 19.3 | 137 |

| 1.25 | 432 | 819 | ||||||||||||||

| 1.6 | 553 | 1048 | ||||||||||||||

| 2 | 677 | 1284 | ||||||||||||||

| 2.5 | 821 | 1556 | ||||||||||||||

| 3.15 | 1858 | |||||||||||||||

| 4 | 2202 | |||||||||||||||

| TD75 | B1400 | 350/600 | 1 | 469 | 891 | 5.25 | 6.07 | 7.1 | 7.93 | 9.02 | 9.85 | 11.5 | 13.5 | 17.8 | 22.6 | 164 |