Air Swept Coal Mill

Air Swept Coal Mill Introduction

The air-swept coal mill produced by AGICO equipment has reasonable structure, high grinding efficiency, strong adaptation to raw materials, which is the ideal equipment for pulverized coal preparation.

Feeding device sends raw coals into drying oven; drying oven is equipped with special lifting plate to scatter coal and make coal get strong heat exchange so that raw coal is dried; dry raw coal is sent into grinding storehouse via double-compartment plate. Grinding storehouse is equipped with grinding balls so that raw coal can be crushed and ground into coal powder in this compartment, while, a dedicated induced draft fan carries over pulverized coal together with gas through discharging device, and coarse particles return back grinding storehouse for re-grinding.

The air-swept coal mill is used for drying and grinding coal powder. It is mainly composed of feeding device, main bearing, rotary part, transmission device, driving device, high-voltage starting device and lubrication system. The raw materials are loaded into the mill through the feeding equipment, and the hot air enters the mill through the air inlet pipe. With the rotation of the mill cylinder, the coal and the hot air exchange heat in the mill, and the coal is crushed and ground in the mill. While the coal is being ground, the fine powder is taken out of the mill through the discharge device through the hot air in the mill. The air-swept coal mill has a reasonable structure and high grinding efficiency, and is an ideal equipment for coal powder preparation.

| Specifications | drawing number | Weight (t) | Main technical performance | Design capacity (t/h) | motor | reducer | |

| model power | model | speed ratio | |||||

|

Φ2.2X4.4M air swept coal mill |

M1002.00U (I) | 38.738 |

Feeding material ≤25mm fineness 88μm sieve remaining 10-12% speed: 22r/min ball loading capacity: maximum 20t |

8-9 | 250KW | ZD60 | 6.3 |

|

Φ2.4X8M air swept coal mill |

MFG2480.00 | 75.91 |

Feed ≤ 20mm, mill output less than 1mm greater than 320㎡/kg greater than 60% Speed: 21.4r/min Ball loading capacity: 30t |

12-13 | 475KW | ZD80 | 5 |

|

Φ2.8X8M air swept coal mill |

M3210.00 | 105 |

The moisture content of the incoming raw coal is less than 10%, and the sieve residue of 80μm sieve is less than 12%. Speed: 19.04r/min Ball capacity: 32t |

16-17 |

500KW 11KW |

JDX630 with lubrication KZN-250 |

5.6 90 |

|

Φ3X9M air swept coal mill |

MM3090.00 | 127 |

The moisture content of the incoming raw coal is less than 10%, and the sieve residue of the 88μm hole sieve is less than 10-12%. Speed: 18.3r/min . |

18-22 |

630 11 |

JDX630 ZSY250 |

5.6 90 |

|

Φ3.2X9M air swept coal mill |

MM3290.00 | 150.385 |

Feed ≤25mm (80% pass rate), fineness 88μm sieve remaining 10-12% Speed: 18.25r/min Ball capacity: 53t |

18-22 |

710 11 |

JDX710 ZSY250 |

5.690 |

|

Φ3.4X9M air swept coal mill |

CF167.00G | 167.168 |

Feeding material ≤20mm (80% pass rate), fineness 88μm hole sieve 6-8% remaining speed: 17.61r/min Ball capacity: 58t |

30 |

900 18.5 |

JDX800 ZSY280 |

7.1 100 |

|

Φ3.6X9M air swept coal mill |

MFB3609 | 190.65 |

Feed material ≤ 20mm Moisture content of feed material is less than 12%, moisture content of discharge material is less than 1%, fineness 80μm hole sieve remaining 6-8% Rotational speed: 17r/min Ball loading capacity: 60t |

30-32 |

1000KW 15 |

MBY800 ZSY250 |

6.3 100 |

|

Φ3.8X9.5M air swept coal mill |

MM3895.00 | 208.65 |

Feeding material ≤20mm (80% pass rate), fineness 88μm hole sieve 3-5% remaining speed: 16.7r/min Ball loading capacity: 88t |

36-40 |

1400 22 |

JDX80 YNS620 |

5.6 90 |

Advantages of air swept coal mill

- The feeding device of the air-swept coal mill adopts a louver-type structure with oblique air intake, which enhances the heat exchange capacity of the mill and can effectively prevent material blocking at the entrance of the coal mill; optimize the support system, improve the lubrication structure, and reduce system resistance.

- The air-swept coal mill adopts an advanced control system, with stable start and transmission, and high economic benefits.

- The air-swept coal mill reduces power consumption per unit of production during operation, saving 20-30% of power consumption; due to the reasonable allocation of steel balls and cylinder lengths by the machine, the production increase reaches 15%-25%. Therefore, the power consumption is low and the production capacity is large.

Working principle of air swept coal mill

The air-swept coal mill has two functions of drying and grinding. When it is working, the raw material is loaded into the mill through the feeding equipment, and the hot air enters the mill through the air inlet pipe. , coal and hot air exchange heat in the mill, the coal is crushed and ground in the mill, while the coal is crushed, the pulverized coal powder and gas are taken out together by the special induced draft fan through the discharge device of the mill In the mill, the coarser particles will return to the grinding chamber through the return screw of the discharge device for re-grinding.

Feeding device sends raw coals into drying oven; drying oven is equipped with special lifting plate to scatter coal and make coal get strong heat exchange so that raw coal is dried; dry raw coal is sent into grinding storehouse via double-compartment plate. is equipped with grinding balls so that raw coal can be crushed and ground into coal powder in this compartment, while, a dedicated induced draft fan carries over pulverized coal together with gas through discharging device, and coarse particles return back grinding storehouse for re-grinding

The air-swept coal mill produced by AGICO equipment has reasonable structure, high grinding efficiency, strong adaptation to raw materials, which is the ideal equipment for pulverized coal preparation.

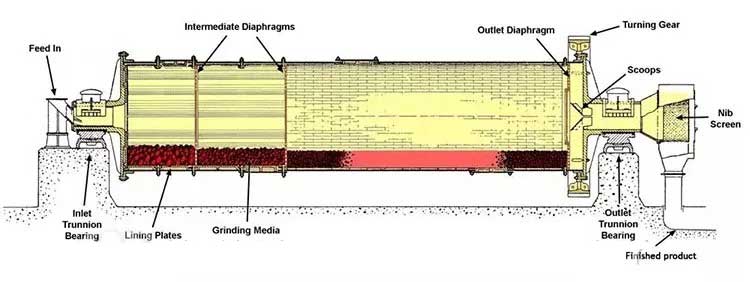

Air-swept coal mill is mainly composed of feeding device, main bearing, rotary part, transmission device, feeding and discharging device, high-voltage starting device and lubrication system. The feeding device is composed of a feeding pipe, an air inlet pipe and a bracket. The feeding device of this mill adopts a louver structure with oblique air inlet and oblique feeding, which makes the feeding more smooth, and the discharging device adopts a curved tube structure.

The air-swept coal mill is an equipment used to grind and dry coal of various hardnesses. It is a machine for crushing coal blocks and grinding them into coal powder. In addition, the air-swept coal mill produced by our company has improved the traditional air-swept mill, the output has been greatly improved, and the output powder is fine, providing a new type of energy-saving grinding equipment for manufacturers.