Vertical Shaft Lime Kiln

- Product introduction: Lime shaft kiln, is a vertical kiln for burning lime. The lime shaft kiln produced by AGICO is a modern lime kiln with environmental protection, energy-saving functions, mechanization and automation. Using modern technology, it can make full use of cheap energy, especially the gas that pollutes the environment (such as converter gas, blast furnace gas, calcium carbide furnace tail gas, etc.) as the main energy source, turning waste into treasure.

- Capacity: 50-400(t/d)

- Granularity of limestone entering the kiln: 30~80/80~120(mm)

- Calcination temperature: 1100±50°

- Scope: Suitable for metallurgy, building materials, calcium carbide, nano-calcium carbonate, aerated concrete, sugar and other industries.

Active lime rotary kiln Cases

100-150 TPD Lime Kiln

100-150 TPD Lime Kiln 150-220 TPD Lime Kiln

150-220 TPD Lime Kiln 300-420 TPD Lime Kiln

300-420 TPD Lime KilnActive lime vertical kiln equipment supporting

-

Calcination of limestone

Qualified limestone goes to the top of the preheater through the belt conveyor, and the material is introduced into the body of the preheater from the silo at the top of the preheater through the discharge chute, and at the same time, the high-temperature flue gas from the rotary kiln preheats the material to 600°C Above, the limestone is partially decomposed, and then pushed into the tail of the rotary kiln by multiple hydraulic push rods one by one, after being calcined at a high temperature in the rotary kiln, it is discharged into the cooler, and the material is cooled to 100°C by the cold air blown by the fan. The cooler is discharged from the bottom, and the air blown through the cooler enters the rotary kiln as secondary air to participate in calcination. -

Combustion device

The burner adopts the structure of inner and outer sleeves, and is fixed on the hood of the rotary kiln. The primary air heated by the heat exchanger is passed into the center tube of the burner, and the mixed gas is passed into the casing of the burner, so that the gas is mixed evenly and the combustion is complete. . -

Flue gas treatment

The high-temperature flue gas produced by the combustion of the rotary kiln, after heat exchange with limestone in the preheater, the temperature drops below 250°C, and then heat exchange through the heat exchanger, the flue gas temperature further drops below 220°C, Then carry out a bag-type dust collector, after dust removal, it is discharged into the atmosphere through a high-temperature fan, and the dust concentration of the exhaust gas is less than 50mg/m3. The heat exchanger heats the combustion air provided by the primary fan to After about 220C, it is sent to the combustion device and used as primary air to participate in calcination. -

Finished product delivery

After the finished lime is discharged from the cooler, it is transported by the chain plate conveyor, and then transported to the finished product silo by the high-inclination belt conveyor.

Lime Shaft Kiln advantages

Lime shaft kiln, opposite to lime rotary kiln , is a vertical cylindrical cylinder equipment with all-steel structure. It uses the principle of heat exchange between material self-weight descending and hot gas rising to carry out lime firing. The company can design and manufacture lime shaft kiln equipment with a production capacity of 50-400 t/d. It is stable and reliable in operation, environmentally friendly and energy-saving, and has a high degree of automation. Various low calorific value converters, blast furnace gas, and calcium carbide furnace tail gas can be used as fuel.

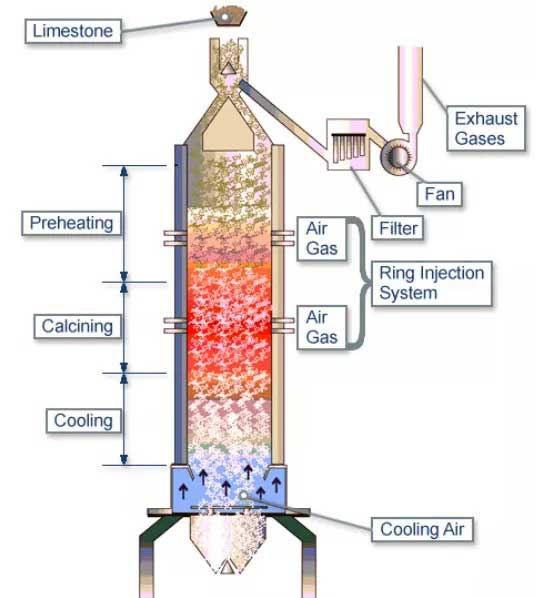

1. Energy saving; inside the vertical kiln there are preheating zone, calcining zone and cooling zone from top to bottom. The cooling air blows into the kiln from the bottom of the cooling zone. After heat exchange, the product is cooled, the cooling air is preheated, and the cooling air carrying heat enters the calcination zone to participate in combustion, thereby reducing energy consumption; The hot flue gas enters the pre-tropical zone to preheat the material at room temperature to the pre-decomposition temperature. The temperature of the flue gas drops to 170-300°C before exiting the kiln.

2. The kiln skin is built by vertical masonry with four layers of refractory materials, which has a good thermal insulation effect. The temperature of the kiln skin can be controlled at about 60°C higher than the ambient temperature, and the energy saving is remarkable.

3. The refractory material has a long service life. The material does not directly collide with the refractory material on the working surface, but relies on gravity to settle and rub against the working surface; this reduces the wear rate of the refractory material; under normal circumstances, the refractory material can be used for 6 to 10 years.

4. Wide range of fuel adaptability; lump coal and coke can be used for co-fired kilns; high calorific value fuels such as natural gas, coke oven gas, and petroleum gas can be used for gas-fired kilns, as well as converter gas, blast furnace gas, calcium carbide furnace tail gas, semi-coke Gas, producer gas and other low calorific value fuels; oil-fired kilns can use liquid fuels such as heavy oil and diesel.

5. Small floor area; due to the vertical arrangement of the shaft kiln, the large-angle arrangement of the single-bucket elevator for feeding, and the compact layout of each functional area, the floor space is reduced;

6. Low investment; less machined parts for the steel structure of the kiln body, lower processing costs; easy installation and low difficulty in masonry with refractory materials.

Lime Shaft Kiln Types

Twin Shaft Lime Kiln

Twin Shaft Lime Kiln Annular Lime Kiln

Annular Lime Kiln Double Beam Lime Kiln

Double Beam Lime KilnLime Shaft Kiln working principle

The shaft kiln is a cylindrical kiln body, the material is fed from the top of the kiln, and discharged from the bottom of the kiln after calcination. According to the temperature change and distribution in the shaft kiln, the shaft kiln is divided into three zones from top to bottom: preheating zone, calcination zone, and cooling zone; in the preheating zone, materials are preheated by the heat of flue gas; , the material is calcined with the help of the heat released by fuel combustion; in the cooling zone, the calcined material exchanges heat with the blown cold air, the material itself is cooled, and the air is heated and enters the calcination zone as combustion air. In order to ensure that all stages of the material calcination process are fully and completely carried out, the three belts in the shaft kiln should maintain a certain height and strive to be stable. There are two reasons for the movement of materials in the shaft kiln: one is the movement of the upper material due to the volume shrinkage of the material during the calcination process; the other is the movement of the whole kiln material due to the discharge of the lower material.

During the descending process, the material undergoes complex heat exchange with the hot gas, accompanied by the decomposition of limestone and the development and growth of quicklime grains. When the whole process is completed, it is also cooled by the combustion air to a temperature 60 degrees higher than the ambient temperature. ℃. Then, the lime is discharged to the belt conveyor outside the furnace by the disc ash discharger and the two-stage sealing valve without leakage of the combustion-supporting air. Lime of ≤5mm and >5mm will be unloaded into different silos after being hoisted and screened.

Combustion-supporting air is blown into the furnace from the lower part of the furnace body by the Roots blower, and rises from the lower part to the top of the furnace overcoming the resistance of the material particles. Under the suction of the dust removal induced draft fan, the flue gas is transported to the dust collector through the pipeline for dust removal. Due to the action of the induced draft fan, a slight negative pressure zone (about -10Pa) is formed above the material surface in the kiln. This slight negative pressure ensures the smooth air flow in the furnace, which is very beneficial to the decomposition of limestone with calcination. The induced draft fan will introduce all the flue gas into the dust collector for purification, and then discharge it into the atmosphere from the chimney up to the standard.

- Lime shaft kiln, including outer wall, inner lining, load-bearing bottom plate in the kiln body, circular operation room and air inlet channel, reinforced concrete main column and foundation structure of the inner supporting wall under the kiln.

- That is, there are several air inlets on the load-bearing floor supported by the supporting wall and the main column in the kiln body, and the ash outlet, the tower-shaped grate and the furnace shed are connected with the load-bearing floor with air inlets.

- The operating room, which is the air inlet channel of the kiln body, is also in communication with the air inlet hole on the outer wall of the kiln and the operation hole and air inlet on the inner support wall. Sliding door controls on top.

- Due to the enlarged ventilation surface and the significantly increased oxygen supply, the coal can be fully burned, thereby increasing the output. Compared with the original invention* with the same volume, the energy saving is about 10%, and the output is increased by 20%.

- A sliding plate steel air door is arranged on the operation hole and air inlet, and the lime storage bin and the kiln body are closed, so the air volume entering the kiln body can be controlled here.

Vertical Shaft Lime Kiln Capacity and Fuel

| Technical Parameters Of Vertical Lime Kiln (Mixed Fuel) | |||||||

| Capacity (t/d) | Effective Volume | Effective Height | Effective Section | Limestone Size | Heat Consumption | CaO | Activity |

| (m3) | (m) | Dia, (m) | (mm) | (kJ/kg) | (%) | (mL) | |

| 100 | 98 | 20 | 02.5 | 30-60/40-80 | <4600 | >90 | >300 |

| 120 | 141 | 20 | 03.0 | 30-60/40-80 | <4600 | >90 | >300 |

| 150 | 202 | 21 | 03.5 | 30-60/40-80 | <4500 | >90 | >300 |

| 200 | 301 | 24 | 04.0 | 30-60/40-80 | <4500 | >90 | >300 |

| 300 | 397 | 25 | 04.5 | 30-60/40-80 | <4400 | >90 | >300 |

| 400 | 491 | 25 | 05.0 | 30-60/40-80 | <4200 | >90 | >300 |

| 500 | 735 | 26 | 06.0 | 30-60/40-80 | <4200 | >90 | >300 |

| Remarks: All above data are for reference only. | |||||||

| Technical Parameters Of Vertical Lime Kiln (Fuel: Gas) | |||||||

| Capacity (t/d) | Effective Volume | Effective Height | Effective Section | Limestone Size | Heat Consumption | CaO | Activity |

| (m3) | (E) | Dia, or LxW (m) | (mm) | (kJ/kg) | (%) | (mL) | |

| 50 | 70 | 20 | 02.0 | 30-60/40-80 | <4600 | >90 | >300 |

| 70 | 80 | 20 | 02.5 | 30-60/40-80 | <4600 | >90 | >300 |

| 80 | 100 | 20 | 02.5 | 30-60/40-80 | <4500 | >90 | >300 |

| 100 | 120 | 20 | 02.7 | 30-60/40-80 | <4500 | >90 | >300 |

| 120 | 140 | 20 | 03.0 | 30-60/40-80 | <4400 | >90 | >300 |

| 130 | 150 | 21 | 03.0 | <4200 | |||

| 150 | 200 | 20 | 25x4.5 | 30-60/40-80 | <4200 | ||

Lime Shaft Kiln Technical Parameters

| Capacity (t/d) | 50 | 100 | 150 | 200 | 300 | 400 |

| Major equipment | Main supporting equipment models and technical and economic indicators | |||||

| Distributor | BL-1 | BL-2 | BL-2 | BL-3 | BL-3 | BL-4V |

| Shaft kiln | 60m³ | 150m³ | 200m³ | 250m³ | 400m³ | 500m³ |

| Kiln section form | round | |||||

| Ash machine | WF-1 | WF-2 | WF-2 | WF-3 | WF-4 | WF-5 |

| Calcination temperature/℃ | 1100±50 | |||||

| Energy consumption index/(kCal/kg lime) | 950±50 | |||||

| Power consumption index/(kW·h/t lime) | 25±5 | |||||

| limestone: lime | 1.6~1.75:1 | |||||

| Lime burning rate/% | ≤13 | |||||

| Lime activity/ml | 220~280 (depending on the composition of limestone) | |||||

| Ash temperature/℃ | Ambient temperature +60 | |||||

| Granularity of limestone entering the kiln/mm | 30~80/80~120 | |||||

| Emission concentration/(mg/Nm3) | ≤30 | |||||

| Number of working days per year/day | ≥340 | |||||

| Overhaul cycle/ year | 3~5 | |||||

| Number of operators/(person/class) | 2 | |||||

| Applicable fuel | Lump anthracite, lump coke, lump petroleum coke, coke oven gas, semi-coke furnace gas, converter gas, blast furnace gas, calcium carbide furnace gas, etc. | |||||