Why Seperator Is Crucial In Cenment Plant

Advantages of Using a Seperator

With the increase of cement mill dimension and the energy-saving, high-yield and high-quality requirements for cement grinding, the use of closed-circuit grinding is an inevitable cement grinding technology trend. One necessary equipment for closed-circuit grinding is the seperator. The seperator function is to select particles with a certain particle size in the milled material in time. Powder sorting machine itself does not produce fine powder, but since the fine particle material can be selected in time, material coagulation in grinding process, adhesion of the grinding body and the sticky phenomenon in warehouse are avoided, and the grinding material can be saved from over grinding; Adjust the varieties of cement production, produce high-fine cement, and improve grinding efficiency.

How Does Seperator Works

The closed-circuit grinding system of the pre-grinding equipment, during the grinding process, the material entering the mill by the grinding head is crushed in a warehouse, quickly passes through first bin by the gaps of balls, and enters the second bin through the compartment plate. The effect of the grinding body in the second bin on the material is mainly grinding, which means crushing effect is small. Small grinding ball is driven by the mill cylinder, and the motion state is swaying, rolling and sliding. The abrasive ball grinds and peels off the material particles during sloping and swaying. If the material cannot be discharged to the outside of the circulation system after being ground, the residence time in the mill will be longer, and the more it will accumulate, the grinding body will continue to grind and peel off the fine particles, which will cause the material to be overgrinded. Therefore, improving the ability of the seperator to select fine powder helps the grinding machine to fully exert its grinding ability. So seperator is an important part of cement grinding system. The operating parameters of the seperator are related to the production of entire unit. If sorting efficiency of the seperator is higher, so is output of the cement mill. In the closed loop system, the focus of cement grinding is mainly on the role of relatively coarse grade particles.

The Main Functions of Seperator

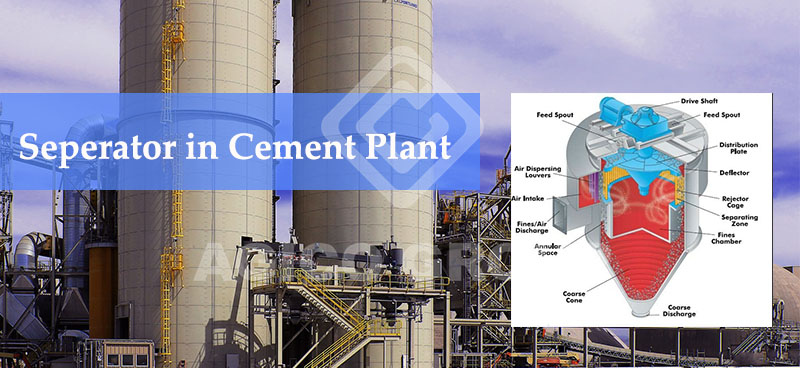

The main functions of the seperator can be summarized as: "dispersion", "grading", "collection". Dispersion means that the material entering the seperator should be spread as much as possible, and a certain spatial distance should be formed between the particles. Therefore, the structure of spreading disc, rotational speed, spreading material size, material moisture and the flow rate of the material directly affect the fabric and the dispersion effect. Grading means that the dispersed material is sorted by various forms of airflow during the limited residence time of the powder selection chamber. The coarse and fine particles should be separated as much as possible by the airflow and sent to the respective outlets. Collection is the ability to capture coarse and fine powders, depending on the manner of collection and the structural form of collection components. Therefore, the gas flow rate, air flow velocity, air flow mode, gas-solid junction and flow field distribution, and the number and structure of the powder selection chamber have a great influence on the classification efficiency.