Kiln Cooler for Cement Rotary Kiln of Dry Process Method

In recent years, with the improvement of large-scale cloth bag dust collecting technology in China, the long bag dust collector technology used in rotary kiln tail gas treatment of cement rotary kiln with dry process method is increasing day by day. The high temperature exhaust gas from the rotary kiln end needs to be cooled to below 250℃ before it enters the long bag dust collector. Kiln Cooler Types of rotary kiln tail gas can be divided into two categories: one is mixed with cold air, the other is cooler.

Old-type small dry rotary kilns are mostly the former. Mixing cold air is simple and easy, less investment, but high energy consumption. In recent years, various forms of rotary kiln tail gas cooler (kiln cooler)have been developed in China, which play an important role in improving the efficiency of long bag dust collector.

Rotary Kiln Tail Cooling Equipment Types

Rotary kiln tail gas cooler is a kind of equipment for heat exchange between 2 kinds of fluid medium with different temperature in mutual isolation. Different from other heat exchangers, the hot medium has higher temperature, lower density, higher flow rate and higher dust content, which brings some difficulties to design and manufacture.

Until now, there are mainly 2 categories and 4 types of air coolers in China. According to the cooling medium, it is divided into water cooler and air cooler, and air cooler is divided into forced ventilation type and natural ventilation type. The forced ventilation type is divided into axial flow type and centrifugal type according to the flow direction of the cooling medium and the different fan. In all 4 types of waste gas kiln coolers, the hot waste gas is forced to flow in the pipe from top to bottom. The cooling medium flows outside the pipe for convective heat transfer.

Water-medium Cooler

In the water cooler, the cooling water flows through the confined space between the shell and the hot tube from bottom to top, with a slower flow rate, and the heat exchange form with the hot exhaust tube is laminar flow heat exchange. Although the heat transfer coefficient is lower than the turbulence state of the same medium, the heat transfer coefficient of the water cooler is still much higher than that of the air cooler, which is about 200 times higher than that of the air cooler, because the density of water is much higher than that of the air cooler.

Natural Ventilation Type Cooler

The cooler has no closed shell, the hot exhaust pipe is exposed to the atmosphere, and the cooling medium is ambient air. The heat exchange mechanism is as follows: the air in a thin layer adjacent to the tube wall surface is heated, the temperature rises, the density decreases, and thus flows upward along the hot surface. The air temperature decreases with the distance from the heat pipe surface. After a certain distance from the surface, the air temperature does not change, but is the same as the atmosphere temperature. The heat transfer coefficient is small because the cooling air velocity is slow and the air density is low. Therefore, only by increasing the heat transfer area can the heat transfer effect be improved. This kind of cooler equipment is huge, but there is no power consumption.

Forced Ventilation Type Cooler

The cooler has an incomplete enclosure. In a cooler using an axial flow fan, several axial flow fans are arranged along a hot row on one side. Both sides of axial flow fan are shielded by shell. Cooling air passes horizontally through several rows of heat pipes. In the centrifugal ventilator cooler, there is a closed shell all around, leaving only the inlet and outlet in the upper and lower parts. The cold air is blown in from the lower part by one (or two) fans, and after the countercurrent heat transfer along the direction of the row pipe, it flows out from the opening of the upper shell. Due to forced ventilation, the flow rate is high, generally above 12m/s, so the cold air flow belongs to the turbulence range. Convection heat transfer is the main form of heat transfer. The main factor determining the heat transfer strength depends on the thermal resistance in the boundary layer. The higher the air velocity is, the thinner the thermal boundary layer is, the smaller the thermal resistance is, and the stronger the heat exchange capacity is.

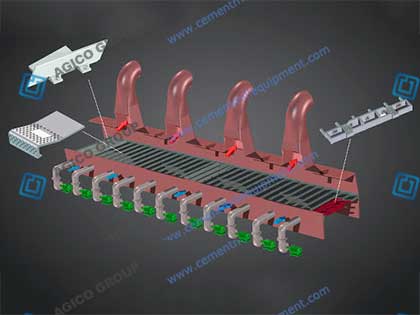

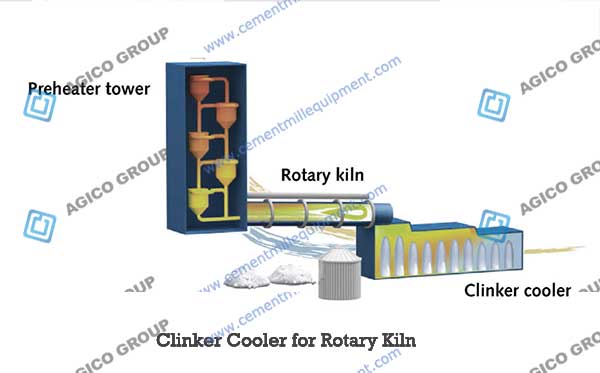

AGICO supplies 2 types of kiln cooler equipment for cement production line, one is grate cooler, the other is rotary cooler, grate cooler is more efficient in cement plant, rotary cooler is suitable for many other industries.Grate Cooler is a type of quench cooler. Its works by quenching clinker which is laid in levels on the grate plates with cold wind from air blower. Grate clinker temperature will be rapidly dropped from 1400º C to be less than 100º C. Plenty of waste gases after cooling could not only be used as secondary air in the rotary kiln, but also be heat source for drying coal in the coal mill.