Introduction of Oil Lubrication Details on Ball Mill Gears

The edge drive size gear is one of the key vulnerable parts of ball mill Equipment. Material selection and lubrication is good or not has a great influence on normal operation of large and small gears. In order to ensure a high service life of large and small gears and a high working performance of grinding machine, selection and lubrication of gear materials must be suitable. AGICO will introduce to you on topic of how to solve wear problem of ball mill size .

Factors that Influences Ball Mill Gears:

Gear material selection of edge drive size gear, the damage is mainly due to wear and bending of the tooth surface. Therefore, gear material is required to have sufficient strength, high wear resistance, and good workability. At present, the material of large ring gear is generally ZG270~500 and ZG310~570, but it must be normalized before processing to reduce hardness to HB170~200. The pinion gear is made of materials such as 35SiMn, 45MnB, and 40Cr.

Tooth profile and number of teeth of the gear have been used in the design before displacement gear, which can improve sliding ratio and improve load carrying capacity. In addition, a multi-tooth number and a small modulus gear are used. It is recommended to use a 25 degree meshing angle plus a deformed tooth profile to improve smoothness, reduce mass, reduce cost and root bending stress.

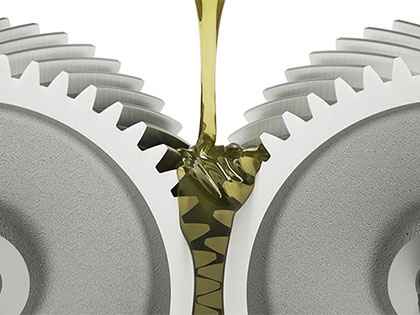

Lubrication Methods of Ball Mill Gears

In general, there are 3 forms of lubrication for large and small gear-lubricated gears: oil pump lubrication, large ring gear with oil lubrication, and oil wheel with oil lubrication.

The oil pump injection lubrication: This method has certain disadvantages. Because ofthe gear pump is applicated for oil supply, the oil can only be a thin oil, so it is easy to wear the large and small gears and the oil pump. Secondly, the gear cover is not sufficiently tightly sealed, and it is easy to enter dust, thereby aggravating wear. Furthermore, maintenance work is not convenient.

Large ring gear with oil lubrication: This lubrication method does not require any additional lubrication equipment, devices and components. Use the bottom of large gear cover as an oil pool, open an oil drain hole, install an oil change valve, and add oil to bit indicating device. This is the simplest, most common application, but the lubrication is the worst.

Oil tanker with oil lubrication: Oil tanker with oil lubrication overcomes the drawbacks of large ring gear with oil lubrication, so it has been applied. The equipment is easy to maintain and does not have oil leakage problems. It is a good lubrication method.