How to Reduce Production Cost of Cement Vertical Mill

Vertical Mill is currently in the industry processing non-metallic ore application equipment, with years of mill technology innovation, it has become ideal milling equipment in processing cement, steel, building materials and other industries. AGICO Cement has a history of 30 years in the production of vertical mills, and the manufacturer's strong strength and technology are guaranteed.

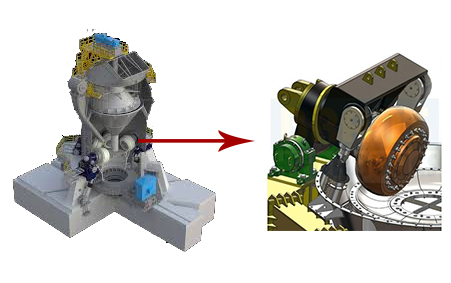

Working Principle of Cement Vertical Mill

In order to reduce the production cost of vertical mill, you first need to understand its construction and working principle. The working principle of vertical mill is that the motor drives the grinding disc rolling through the reducer, the wind also enters the vertical mill body from the air inlet, the slag and other materials fall to the middle of the grinding disc through the feeder outlet, and when the grinding disc is rolled, the material is thrown to the edge of the grinding disc and is crushed by the grinding roller, large material is directly crushed, small particles constitutes the material bed for intergranular destruction.

After the destruction of the slag material arrives at the margin, it is carried away by the strong wind at the wind ring, and the heavier material particles fall on the grinding disc to continue grinding, and after the material in the air flow passes through the upper separator, the coarse particle material is blocked by the rotor blade and returned to the grinding disc to be re-ground. Qualified material is milled with the air flow and collected by the powder collector. In the meantime, the powder separator is to adjust its rotor speed to control the product material fineness, hydraulic system is to adjust grinding roller pressure to adapt to the material due to it’s hardness.

Tips for Reducing Production Cost of Vertical Mill

- After collecting change trend data of vertical mill parameters, such as: pressure difference, material layer thickness, grinding pressure, temperature, oscillation value, air volume, etc., find out the reasons and connections, explore the parameters with low unit energy consumption, and then realize the high yield and high efficiency operation of the milling system.

- The power consumption of the ring fan accounts for about 35% of the power consumption of the entire milling system, so decreasing air volume can effectively reduce the electrical consumption of the wind turbine, and then reduce the electrical consumption of the vertical grinding machine. In addition, leakage in the system should be reduced as less as possible.

-

According to the operation status of the vertical mill, it is necessary to regularly check the wear of the grinding disc and grinding roller liner, adjust the retaining ring height in time, and prevent the grinding efficiency from decreasing, the host load and motor current increases due to the thickness of the material layer, main load would increase with the motor current rise, the scraping plate wear and the gap at mill bottom plate will also affect the power consumption.

The above is the relevant information on how to reduce the production cost of the vertical mill, if you want to know more about this cement plant equipment, send an email to us for customer consultation service, AGICO Cement will offer you with best cement plant solution.