How To Increase Wear Part Of Cement Ball Mill Service Life

In cement production, ball mill is one essential milling equipment in cement grinding, service life of ball mill is always concerned by cement plant owners. In fact, ball mill is composed of a group of components. There are parts are so important that could influnence normal running, also there are parts that will not cause serious problems but only lower the working efficiency. All parts shall be kept in good shape with daily maintenance work.

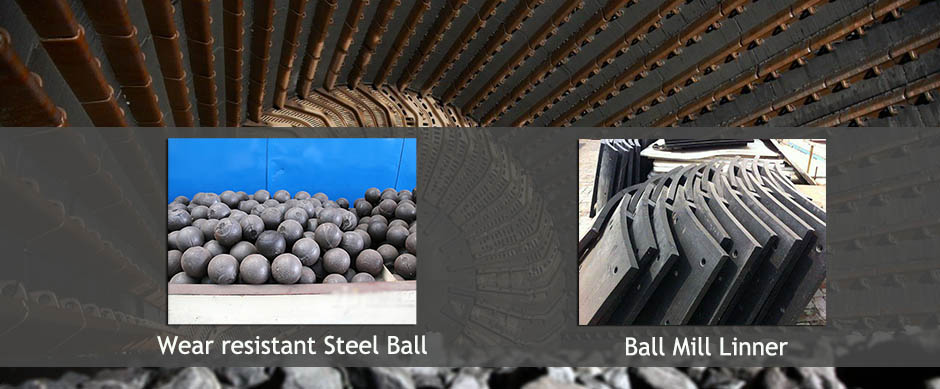

Cement Ball Mill Linner

Abrasion resistance Steel Linner

So which parts are most likely to worn, it is the ones that are bearing large workload, which will lead to shorter service life compared with other parts. For all machineries, it is called wearing part, wearing parts shall be examined frequently for long and efficient production. It is important for normal production to be not interupted by serious equipment problems, good maintenance work can save manpower, material and equipment costs in the long run. If you want to increase the service life of ball mill in cement plant, you should get to know the service life of each wearable part of the equipment and how to examine and do the maintenance work in the right way. With inspection, we can make the results of our judgment more accurate, and timely replacement makes the work more efficient.

Service Life of Wear Parts in Cement Ball Mill

- Cylinder liner used to protect cylinder shell from the impact of abrasive media and raw materials. If high-strength steel is used, its average service life is 6~12 months. In daily production, it should reserve at least 2 for each billiard mill. Sleeve body liner;

- The average service life of end cap liner made of high manganese steel is 8~10 months. In daily production, a minimum of two sleeve body liners should be reserved for each billiard mill;

- The average service life of main bearing lining made of babbitt alloy is 24~36 months. In daily production, a set of main bearing lining should be reserved for each billiard mill;

- The average service life of rotary bearing bushing made of babbitt alloy is 18 months. In daily production, at least two sets of rotating bearing bushings should be reserved for each billiard mill;

- The average working life of the liner bolts made of carbon steel is 6~8 months. In daily production, at least 0.5 sets of liner bolts should be reserved for each billiard mill.