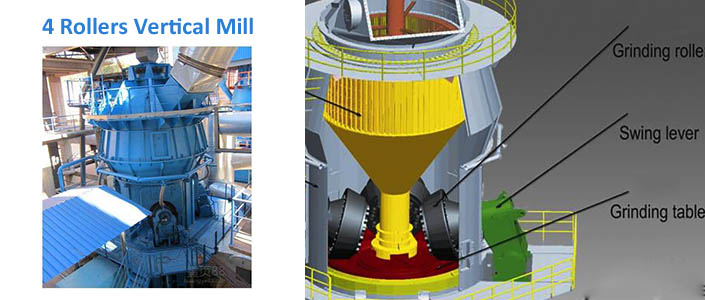

How To Improve Output Of Vertical Mill

How to improve output of Cement vertical mill has always been the concern of users. Due to the lack of attention to some small factors, the output of the vertical mill may be reduced. One of the more obvious performances is that vertical grinding roller and disc liner are worn after a period of use. Invisible is equivalent to increasing the height of the retaining ring, increasing the thickness of the material layer, increasing the load of the main motor, and limiting the output, which has a great influence on the working condition of vertical mill. In the case of not changing the roll skin and the disc liner, reducing height method of the retaining ring according to wear condition can restore the mill capacity in a short time. The following is the full analysis.

Analysis of Vertical Mill Output

-

Grinding rolls and grinding discs are seriously worn

The vertical mill disc liner has not been replaced since it was put into production, and its surface wear is serious. After measurement, disc liner wear reaches 20mm, the layer thickness increases during operation, the average thickness is 145mm, the main motor current is high, and the output is limited. -

The height of the retaining ring

After measuring the height of the retaining ring is 105mm, the wear of the disc liner is up to 20mm, which is equivalent to increasing the height of the retaining ring. The difficult-to-grind material is difficult to be thrown out in time, the thickness of the layer is increased, and the current of the main motor is increased. -

Wind chamber floor wear

Due to the long-term scouring of the materials in the wind chamber, the bottom plate on the outer side of the squeegee is more severely worn, forming a bowl shape, and the phenomenon of wear and leakage has appeared locally. The material is easy to accumulate, the gap between the squeegee and the bottom plate becomes larger, the resistance increases when the material is scraped, and the current of the mill rises.

Vertical Mill Renovation Measures

-

Lower the height of the retaining ring

Under the premise of not changing the roll skin and the disc liner, the height of the retaining ring is adjusted from 105mm to 85mm according to the wear amount of the disc liner, so that the hard-to-grind material can be removed in time and the thickness of the layer is reduced. -

Repair the bottom plate

After observation and measurement, the larger gap between the outer side of the scraper and the bottom plate is 150mm, and the larger gap between the inner side and the bottom plate is 80mm. It can be seen that the severe wear of the floor of the wind chamber is mainly between the center line of the scraper and the casing (see Figure 1). To this end, we use a steel plate that is consistent with the curvature of the bottom plate to cover the weld, keep the bottom plate flat, and adjust the scraper to make the gap with the bottom plate reach a reasonable range.