How to Evaluate Seperator Working Performance

Ways to evaluate Seperator working performance

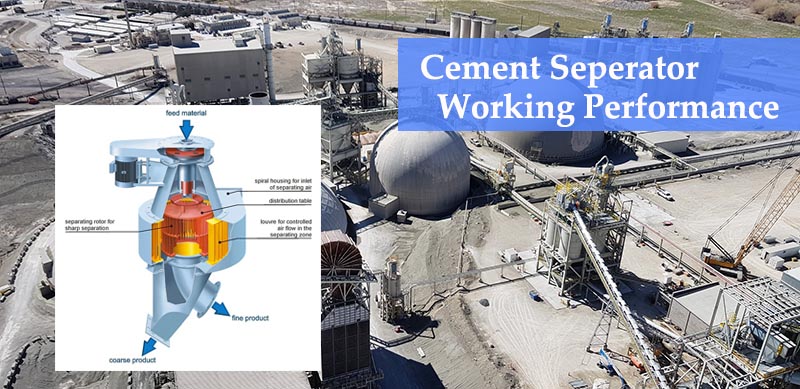

The influence of seperator on working condition of cement mill is mainly reflected by powder selection efficiency, cycle load rate and grinding efficiency of cement mill. Powder selection efficiency (E): It is a technical parameter indicating the selecting ability of seperator. Refers to subdivision ratio of a certain grade in the finished product after the powder selection to the content of the fraction in the feeder of the seperator.

The high efficiency of powder selection means that cement seperator machine can select more fine powder from milled material, and cement ball mill output of the closed-circuit grinding system is measured by the amount of filtered fine powder. Therefore, The high efficiency of powder selection is beneficial to increase output of cement mill.

|

E=(100-g/100-a)×(b-a/b-g)×100% (2)

|

|

g, a, b - the fineness (passing amount) of the finished product, the grinding and returning powder respectively;

|

|

|

|

Cycle load rate (L): refers to the ratio of the feed amount B of the seperator to the finished product (feed amount) G:

|

|

L=B/G=(a-g)/(b-a) ×100% (3)

|

|

|

|

There is the following relationship between the powder selection efficiency E and the cyclic load rate L:

|

|

E=(g/a)(1/1+L) ×100% (4)

|

The cycle load of the seperator is closely related to comprehensive performance of the system equipment, internal ventilation of the mill, and abrasive body grading.

Balance of Cyclic Load

Large cyclic load and too much amount of material in the mill is likely to affect grinding efficiency; the cycle load rate reflects the cooperation of cement ball mill and seperator. At the same time, the cycle load rate also shows the length of time the material stays in ball mill. High cyclic load rate indicates that the material stays in the mill for a short period of time, the grinding degree may be insufficient. Which will lead to less fine powder content in milled material, so out put of cement milling is limited. If the cycle load rate is too low, material residence time in the mill is too long, and the qualified fine powder cannot be ground in time, and the phenomenon of over-grinding is likely to occur, resulting in a decrease in the grinding efficiency and affecting the mill output. Therefore, it is necessary to operate at an appropriate cyclic load rate to improve cement milling efficiency.

How to Improve Ball Miller Grinding Efficiency

For the same milling system, ball miller grinding effect can be increased through 2 aspects: increase cyclic load and higher efficiency of powder selection. which decreases as the cycle load increases. Therefore, in the production process, neither the one-sided pursuit of powder selection efficiency nor the excessive increase of the cyclic load is the right way to acheive it. It is necessary to increase powder selection efficiency under a suitable cyclic load, so as to effectively improve the grinding efficiency. In general, the longer the ball mill, the lower the cyclic load rate. The finer the fineness of finished product, the greater the cyclic load rate. Increase of cyclic load rate means that the amount of material passing through the mill increases; the amount of material fed to seperator increases, and the separation is less easy; seperator load increases, and powder selection efficiency is inevitably reduced. It can be seen from equation (4) that the cyclic load rate is inversely proportional to the efficiency of the powder selection.

Tips for Evaluate Comprehensive Performance of Seperator:

One is the efficiency of the powder selection; the other is the percentage of the particles of 3 to 30 μm in the separated finished product. Because the particles in this interval are the best part of the strength of the cement. The efficiency of the powder selection directly affects the mill output. Too low powder selection efficiency will produce mill output; too high powder selection efficiency, 30-80μm particles occupy a large proportion in the finished product, the specific surface area of the cement is reduced, and the cement strength is reduced. Therefore, too high and too low powder selection efficiency is not an ideal indicator. In actual production, cement seperator working performance is evaluated. The simplest method is to determine the particles percentage of ≤30μm in the return material. The less the content of ≤30μm in the return material, the better the performance of the seperator.