Cyclone Preheater Design for 5500 Ton Cement Production Line

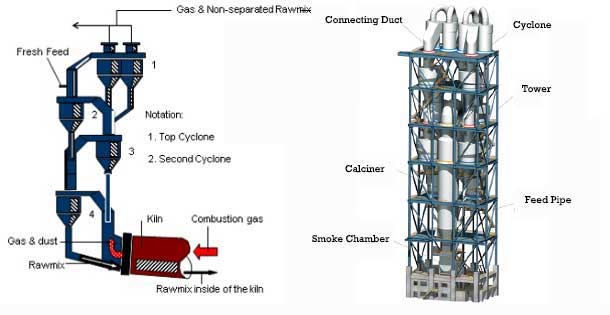

Cyclone preheater is one of the core equipment in the new dry cement production process, which is responsible for many functions such as gas-solid dispersion, material heating, gas-solid separation, material transportation and some physical and chemical reactions.

Separation efficiency and resistance loss are two main performance indexes to be considered in the design of cyclone preheater.

Cyclone Preheater and Rotary Kiln History

The world's first cyclone preheater kiln was put into production by Humboldt in 1951. After more than 40 years of development, Humboldt introduced a new and improved cyclone preheater in the early 1990s. JY, XJ, ZG, SD, YN and other cement production lines have been used in China for this new type of preheater, and the overall application is fine. All cement production lines basically meet or exceed the design targets, among which JY 5500T /d cement production line exceeds more than a quarter of the designed output. A comprehensive and systematic study and analysis of the key equipment of these production lines with ideal overall performance can improve the level of new dry cement production technology in China from a high starting point, which is beneficial to promote the progress of the industry. For this reason, we have carried on the system comprehensive test and the determination research to the top cyclone preheater tube of the new dry method cement production line of JY cement plant.

Test Equipment Details of Cyclone Preheater

The basic function of cyclone preheater is gas-solid separation, and the separation effect is determined by the cyclone structure and the distribution of gas 3-dimensional flow field. In this article, a test system is used to measure the 3-dimensional flow field of gas in the preheater cyclone tube. Meanwhile, the resistance loss of the cyclone tube and the separation characteristics of the cyclone tube are measured in no-load condition. On this basis, the comprehensive analysis and review of the cyclone preheater are made by comparing the actual test data of the cement plant.

Resistance Condition of Cyclone Preheater

| Manufacturer | HX | YX | LY | DX | SC | JY |

|---|---|---|---|---|---|---|

| Ҙi | 8.8 | 9.61 | 8.66 | 7 | 5.2 | 6.1 |

| Ҙav | 122 | 362 | 196 | 256 | 47.5 | 213 |

The basic characteristics of JY 5500T/D top cyclone preheater tube in structure are the adoption of 4-core gradual spiral shell structure, the top center area is convex, the inner cylinder is long, The ratio of the inner cylinder diameter and the diameter of the cylinder segment is a little more than 1:2.

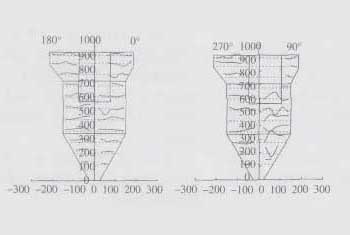

Fig.1 shows the test model of cyclone preheater tube and the measuring points distribution. The cyclone preheater cartridge is reduced by a ratio of 15.83:1.

11 planes are divided along the axial direction of the cyclone cylinder, and each plane is set with holes in four directions along the flow direction: A,B,C and D. Each hole measures the 3-dimensional velocity and pressure of the gas at 4-7 measuring points. The flow field measurement is carried out in the 2 self-modeling area to increase the reliability of the measurement.

The resistance characteristics and separation efficiency of cyclone preheater canister are also measured using intelligent 3-dimensional flow field measurement system and special software.

Measurement and Analysis of 3-dimensional Gas Flow Field of Cyclone Preheater

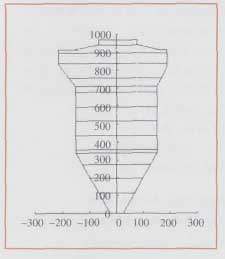

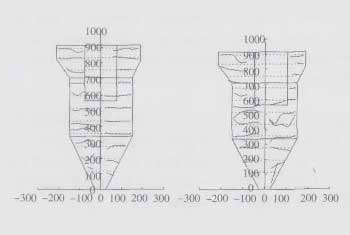

FIG. 2 FIG. 3 and FIG. 4 show the measured results of axial, tangential and radial wind speed distributions of JY(top cyclone preheater cylinder).

In the figure, positive axial wind speed represents axial upward flow, and negative axial flow represents axial downward flow. It can be seen from the axial velocity distribution diagram that the area with relatively high axial velocity is basically located in the area near the inner cylinder and the inner cylinder wall, and is located in this area.

The airflow velocity in outer space is relatively stable. This indicates that the airflow moves downward spiral along the cylinder wall after entering the cyclone cylinder from the inlet, and then turns back upward and moves in an axial direction at the lower part of the cylinder, resulting in certain backmixing, but generally showing a relatively good movement trend. Down the wall of the airflow velocity is helpful for the cone part downward discharge, to reduce the secondary dust float in the sky, thus improving the separation efficiency, but this cyclone tube cone area has a wide range of air flow is upward mobility, is bad for the material of successful eduction down, in the high wind speed or material concentration is greater cause secondary float in the sky.

The tangential movement of the airflow provides the centrifugal force of the material particles. The higher the tangential velocity at the outlet of the cyclone tube is, the greater the force of the material particles will be. From this figure, the new Humboldt cyclone preheater can provide sufficient tangential velocity to improve its separation efficiency. However, the tangential wind speed is large, and the coil and suction are also large when the wind flows from the cone, which may cause the secondary flying, which is also unfavorable for gas-solid separation.

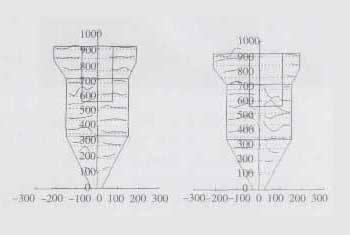

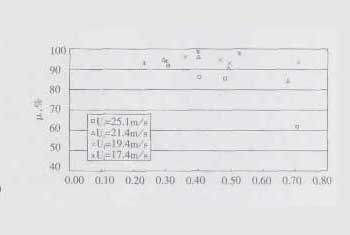

Separation Efficiency of Cyclone Preheater Prototype

FIG. 5 shows the measurement results of separation efficiency. It can be seen that the separation efficiency of the cyclone tube (JY) is the highest at the inlet wind speed of 17.4m/s, reaching about 95%. However, with the increase of inlet wind speed, the separation efficiency decreases gradually. When the cross-section wind speed of the cylinder is about 3.5-3.6m/s, the separation efficiency decreases to 93.8%, and then if the wind speed is further increased, the separation efficiency will rapidly decline (FIG. 4).

Wind Temperature and Pressure Monitor Data

| Position | Temperature | Pressure Pa | C1 Pressure Reduction Pa | |||

|---|---|---|---|---|---|---|

| Measure | Central control value | Measure | Central control value | Measure | Central control value | |

| East C1 outlet | 302.5 | 305.5 | -6690 | -6505 | 1515 | 1585 |

| East C2 outlet | 486.5 | 468.5 | -5175 | -4920 | ||

| West C1 outlet | 304.5 | 301.5 | -6509 | -6220 | 1310 | 1415 |

| West C2 outlet | 481.5 | 486 | -5199 | -4805 | ||

This indicates that the new type of Humboldt cyclone has a good gas-solid separation capability under the condition of low wind speed (the cross-section wind speed of the cylinder is about 3.2m/s or lower), but the separation efficiency is not stable and fluctuates greatly with the change of operating parameters. This is consistent with the analysis result of gas 3-dimensional flow field measurement.