Cement Plant Projects Of Pre-Grinding Equipment Before Ball Mill

Xinjiang Cement Plant Project

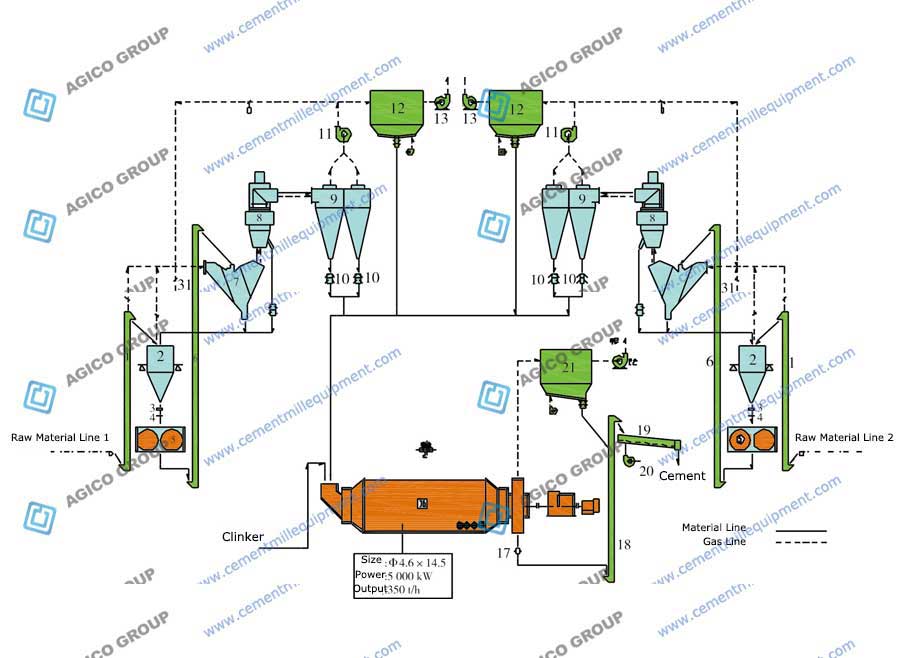

Xinjiang 6000 t/d cement production line for cement precalcining process has the two sets of HFCG180-160 large roller press,its mechanical properties (output 930 ~ 1 050 t/h, 1600 kW main motor power, static classifier mode: HFV5000 + DSM5000 combined the dynamic high fine classifier (spindle motor power 200 kW), graded materials are transmitted to a tall thin tube mill (Φ 4.6 m * 14.5 m) (main motor power 5 000 kW) joint consisting of a large open circuit grinding system,The process flow is shown in Figure 1[1].

When P·O42.5 grade cement is produced and the specific surface area of the finished product is 358 m2/kg, the system output reaches 356 t/h and the grinding power consumption of the cement grinding system is 28.43 kWh/t; When P·C32.5R grade cement is produced and the specific surface area of the finished product is 364 m2/kg, the cement grinding system output reaches 383 t/h and the power consumption is 25.75 kWh/t.

Roller press power/ball mill power = 6,400kW / 5,000kW =1.28; Roll press processing capacity/ball mill output =5.9; Circulating load of roller press system =448% ~ 490%; ball mill grinding diameter ratio = 14.5m / 4.6m =3.15.

Dry Process Cement Production Line (25-200t/d)Configuration

| Capcity | 25t/d | 50 t/d | 100 t/d | 150 t/d | 200 t/d | |

| Rotary kiln | Specification | Φ1.4×33m | Φ1.6/1.9×36m | Φ2.2×45m | Φ2.5×50m | Φ3×60m |

| Capacity | 1t/h | 2t/h | 4t/h | 6t/h | 8t/h | |

|

Calcination Temperature (℃) |

1450 | 1450 | 1450 | 1450 | 1450 | |

| Raw mill | Specification |

Φ1.2×4.5m Open circuit |

Φ1.5×5.7m Open circuit |

Φ1.83×6.1m Open circuit |

Φ1.83×6.1m Closed circuit |

Φ2.2×6.5m Closed circuit |

| Capacity | 1.7t/h | 4.5t/h | 9t/h | 12t/h | 16t/h | |

| Motor power | 55kW | 130kW | 210kW | 210kW | 310kW | |

| Cement mill | Specification | Φ1.2×4.5m Open circuit |

Φ1.5×5.7m Open circuit |

Φ1.83×6.1m Open circuit |

Φ1.83×6.1m Closed circuit |

Φ2.2×6.5m Closed circuit |

| Capacity | 1.4t/h | 3.5t/h | 6.5t/h | 8t/h | 12t/h | |

| Motor power | 55kW | 130kW | 210kW | 210kW | 310kW | |

Technical features:

The cement grinding system makes full use of the grinding roller press section for high efficiency grinding, which has the advantage of more pressing and less grinding, after extruding the material get into the 2-stage(dynamic and static) air classification equipment, material classification is more accurate, working efficiency is higher, the grinded material particles is finer, and has better uniformity (better"crack effect"). The pre-grinding section has replaced the function of the first bin of the ball mill and most of the functions of the fine grinding bin. By adjusting the gradation of the roller press, reducing the grinding body size and increasing the total surface area, it is very significant to improve the fine grinding and shaping ability of the subsequent ball mill. Consists of two large roller press machine per hour extrusion processing material amount > 2000 t/h, which produces less than 80 microns of cement powder for over 600 t, total inlet clinker into the grinding material quantity not less than 450 t/h, through the adjustment of air volume and spindle speed of high fine air classifier, it becomes very convenient to control feeding ball mill of recycle and into the grinding fineness. In this cement plant system, the material specific surface area of the ball mill is more than 300m2 /kg (particle size < 50 m), and the working efficiency of the roller mill section is increased, and the actual power used in the roller press section reaches 9kwh /t, while the actual power used in the ball mill section drops to 11kwh /t. The cement grinding efficiency is significantly improved, and the power consumption of the cement grinding system is greatly reduced. The crushing function of one storehouse is all moved to the outside of the cement ball mill, while the main function of the inside of the mill is fine grinding and shaping, the particle morphology of cement is good with fine working performance.

SM Cement Plant Project

SM cement plant equipments list: The HFCG180-160 large roller press (output 930 ~ 1 050 t/h the main motor power 2*1600 kW + static classifier type HFV4500 HES + under 4500 (B) into a high wind combined fine dynamic classifier (spindle motor power of 200 kW, output 180 t/h ~ 260 t/h) + Φ 3.8 m * 13 m tall thin double storehouse ball mill (2500 kW main motor power, a warehouse effective length of 3.0 m (warehouse long ratio 24%, Loading with 4 levels of grinding balls Φ 30 mm, Φ25 mm, Φ20 mm , Φ17mm 40 t, the average ball diameter 22.9 mm, filling rate 27.27%), effective length of second warehouse is 9.50 m (warehouse long 76%, loading Φ 14 mm * 14 mm, Φ12mm * 12 mm, Φ10 mm x 10 mm level 3 steel section of 135 t, the average diameter of 10.20 mm, filling rate is 27.85%, grinding medium load weight within a total of 175 t) of open circuit cement grinding system.

In production of P·O42.5 grade cement, the finished cement specific surface area of is 360 m2/kg, the system output reaches 240 t/h, and the grinding power consumption of the cement grinding system is 28 kWh/t; In Production of P· C32.5r grade cement, the specific surface area of the finished product was 380 m2/kg, the system output reached 260 t/h, and grinding power consumption was 25 kWh/t. The cement clinker specific surface area was 288 m2/kg.

Roller press power/ball mill power =3 200kW /2 500kW =1.28; Roller press processing capacity/ball mill output > 4.0; Circulating load of roller press system =320%; ball mill grinding diameter ratio = 13m / 3.8m =3.42; The effective length of the second warehouse of the ball mill is 9.5m/the effective length of the first warehouse is 3.0m =3.17.

Guangdong Cement Project

Luofu mountain cement group of guangdong 1.2 million ton output cement grinding station, Equipment List the HFCG180-160 rolling machine (output 930 ~ 1 050 t/h, main motor power of 600 kW * 2) 1 + HFV4500X static classifier + DSM4500(Ⅱ) high fine dynamic classifier, Φ3.2 m *13m double storehouse ball mill (main motor power 1, 600 kW) of open circuit grinding system [2].

System design capacity: P·O42.5 cement output ≥ 140t /h, R80 sieve residue < 2.0%, specific surface area of finished product (380±10)m2/kg, grinding power consumption < 31kwh /t; Actual output of the system: P·O42.5 cement output reached 152 t/h, R80 sieve residue < 1.5%, specific surface area of finished products (390±10)m2/kg, grinding power consumption of the system was 29 kWh/t.

Roller press power/cement ball mill power (installed power ratio) =3 200kW /1 600kW =2; The specific surface area of the extruding semi-finished products sorted by the dynamic and static two-stage high fine air classifier has reached 250 ~ 300 m2/kg. Roller press processing capacity/ball mill output >6.9; Circulating load of roller press system =600%; ball mill grinding diameter ratio =13 m/3.2 m=4.06.

To sum up, improve the cement mill pre-grinding processing ability, using the static and dynamic level air classification equipment, greate reduce the maximum particle size of grinding material, reduce the workload of ball mill by pregrinding with roller press, to make full use of ball mill grinding fine and granular plastic technology advantage, can effectively achieve the power saving purpose in cement grinding system.