5-200 Tons Vertical Kiln Production Line Equipment List

Vertical Kiln Production Line Description

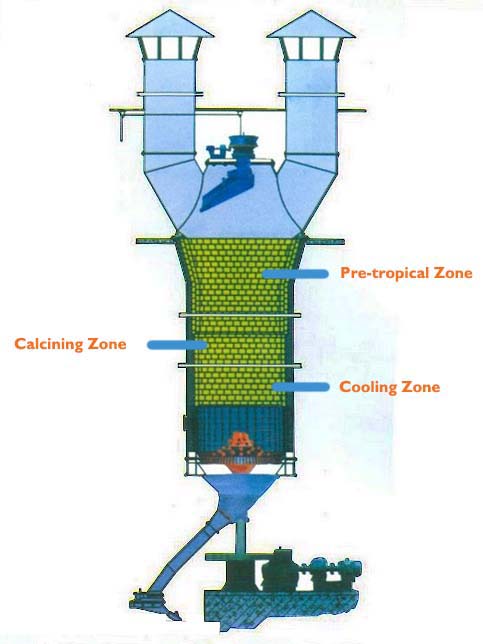

The mechanical shaft kiln is a medium and small-sized cement clinker calcining equipment equipped with a kiln surface, a kiln and a partial fire control system.

The vertical shaft kiln is a cylindrical kiln body, raw material is added from the top of the kiln, and is discharged from kiln bottom. After calcination. According to the temperature variation and distribution, shaft kiln is divided into three regions from top to bottom: pre-tropical zone, calcining zone and cooling zone; in the pre-tropical zone, raw material is preheated by the heat from flue gas burning; in calcining zone, raw material is calcined by means of the heat released by fuel combustion; in cooling zone, calcined material is heat exchanged with the blasted cold air, calcined material is cooled, and exchange air is heated and then enters calcination zone as combustion air. In order to ensure that the various stages of calcination process of material are fully and completely carried out, three belts in the shaft kiln should maintain a certain height and strive to be stable. There are 2 ways for material to move in the shaft kiln: one is the movement caused by volume shrinkage of upper layer material during the calcination process; the other is the movement caused by discharge of lower material in shaft kiln.

Equipment Lists of Vertical Kiln Production Line - 5-200 tons/year

| Serial number | Name specification | technical parameter | Quantity |

|---|---|---|---|

| 1 |

Plate feeder B1000×12.1m |

Q: 18-110T/h N: 15kW | 1 |

| 2 | PE600×900 crusher | Q: 56T/h N: 55KW | 1 |

| 3 | HD8964L-A bag filter |

Q: 4200-5200m3/h N: 7.5KW+0.37KW |

|

| 4 | FF300S flap valve | Q: 6-12T/h | 1 |

| 5 | TD75 tape machine | B650×23.022m Q: 140T/h N: 5.5kW | 1 |

| 6 | PC1010 hammer crusher | Q: 60-80T/h N=132kW | 1 |

| 7 | MW-66-12B sleeve dust removal | Q: 10800-14400m3/h | 1 |

| 8 | Fan | C4-73-11-No5.5C Q=14700m3/h, N=22kW | 1 |

| 9 | TH400 bucket elevator | Q: 58 m3/h N: 15kW | 1 |

| 10 | BZ-1 rod valve | 600×600 | 2 |

| 11 | TDG65 speed scale | Q: 24T/h | 2 |

| 12 | Gate | 400×400 | 4 |

| 13 | TDG50 speed scale | Q: 6.5T/h | 2 |

| 14 | TDG50 speed scale | Q: 1.5T/h | 2 |

| 15 | HD8948C bag filter |

Q: 2000-3000m3/h N: (5.5+0.25) KW |

3 |

| 16 | TD75 tape machine |

B500; L: 38.85m N: 80T/h; N: 5.5kW |

1 |

| 17 | TD75 tape machine |

B500×17.1m; α: 17°; Q: 15T/h; N: 3KW |

1 |

| 18 | 400×600 clay crusher |

Q=10-15T/h; N: 15kW; dv≤400mm; dr≤25mm |

1 |

| 19 | TD75 tape machine |

B500×30.5m; Q: 80T/h α: 15°42'; N: 5.5kW |

1 |

| 20 | TD75 tape machine |

B500×6.1m; Q: 15-20T/h α: 10°23' |

1 |

| 21 | TH315 bucket elevator | C=9.763 Q: 35m3/h; N: 7.5kW | 1 |

| 22 | SM500 coal crusher | Q: 5-8T/h; N: 7.5kW | 1 |

| 23 | TH315 bucket elevator | C=13.347m Q: 35m3/h; N: 7.5kW | 1 |

| 24 | Gate | 200×200 | 1 |

| 25 | GZIF electric vibration machine | N: 60W | 1 |

| 26 | 9-19No6.3A fan | Q: 3972m3/h; P: 9650Pa; N: 18.5kW | 1 |

| 27 | Butterfly valve | 1 | |

| 28 | GJH2212 dryer | Φ2.2×12m; Q:10-60T/h; N:22kW | 1 |

| 29 | DFF300S electric flap | Q: 6-12T/h; N: 0.55kW | 1 |

| 30 | TH315 bucket lifter | C: 26.659; Q: 35m3/h; N: 11kW | 1 |

| 31 | CLK4×60 diffused dust collector | Q=27000m3/h | 1 |

| 32 | DFF220 electric flap valve | N: 0.37kW | 1 |

| 33 | CWB-15 horizontal electric dust collection | Q=30000-37400m3/h; loc>99.5% | 1 |

| 34 | G4-73-11No.9D fan | Q=24000m3/h; P: 2670Pa; N: 30kW | 1 |

| 35 | LS200 screw machine | L: 11m; N: 2.2kW | 1 |

| 36 | MB2270 ball mill | Φ2.2×7m; Q: 20-25T/h; N: 380KW | 1 |

| 37 | DFF400S electric flap valve | Q: 20-60T/h; N: 0.75kW | 1 |

| 38 | TH400 bucket lifter | C=21.152; Q: 58 m3/h; N: 15kW | 1 |

| 39 | QLL4.0m powder separator | N: 45kW; φ4m | 1 |

| 40 | DFF400S electric flap valve | 2 | |

| 41 | LS400 | L = 15.500m; Q: 36.2m3 / h; N: 11kW | 1 |

| 42 | TH315 bucket lifter | C=15.395; Q=35m3/h; N:11kW | 1 |

| 43 | WL300 single tube machine | Φ300×1460m; Q:35T/h; N:3kW | 1 |

| 44 | LS400 screw machine | L=13.500m; Q: 45m3/h; N: 7.5kW | 1 |

| 45 | TH315 bucket lifter | C=21.539; Q= 35m3/h; N:11kW | 1 |

| 46 | CLK2×7 diffused cyclone dust collector | Q: 12900-18400m3/h | 1 |

| 47 | CWB.7 horizontal electric dust collection | Q: 15000-18700m3/h | 1 |

| 48 | DFF150 electric flap valve | 0.37-0.55Kw | 1 |

| 49 | 4-72-11No.6C fan | Q: 15800m3/h; P: 2480Pa; N: 18.5kW | 1 |

| 50 | LS400 screw machine | L = 23.500m; Q: 36.2m3 / h; N: 11kW | 1 |

| 51 | LS400 screw machine | L = 24.500m; Q: 36.2m3 / h; N: 11kW | 1 |

| 52 | LS400 screw machine | L = 24.500m; Q: 36.2m3 / h; N: 11kW | 1 |

| 53 | LS400 screw machine | L=22.500m; Q:36.2m3/h; N:11kW | 1 |

| 54 | HD8948C single bag dust collection | Q: 2000-3000m3/h; N: 5.5kW+0.75kW | 2 |

| 55 | TH315 bucket elevator | C=23.587m; Q:35m3/h; 11KW | 1 |

| 56 | Gate | 300×300 | 1 |

| 57 | LS400 screw machine | L = 8.500m; Q: 36.2m3/h; N: 5.5kW | 1 |

| 58 | Rigid impeller | 300×300 1.5kW | 1 |

| 59 | TH315 bucket elevator | C = 15.3955m; Q: 35m3 / h; 11KW | 1 |

| 60 | TH315 bucket elevator | C=22.051; Q:35m3/h; 11KW | 1 |

| 61 | SWL250×2000 double pipe machine | Q: 11-34m3/h; N: 7.5kW | 1 |

| 62 | LXC-H spiral electronic scale | 1 | |

| 63 | 2J5.5×3000 twin shaft machine | Q: 25T/h; N: 15kW | 1 |

| 64 | QPY36 into a ball machine | Φ3.6m; Q: 18-22T/h; N: 18.5KW | 1 |

| 65 | TD75 belt conveyor | B500×6.5m; Q: 120T/h; N: 5.5kW | 1 |

| 66 | CD0.5-6A electric hoist | 1 | |

| 67 | Φ3×11m mechanical shaft kiln | Q: 11-13T/h | 1 |

| 68 | L94WD Roots blower | Q: 359m3/h, P: 294KPa; N: 245kW | 1 |

| 69 | ZLX-9 muffler | 1 | |

| 70 | LS200 screw machine | L=4m; 2.2kW | 1 |

| 71 | LS200 screw machine | L=8m; 2.2kW | 1 |

| 72 | LS200 screw machine | L=11m; 2.2kW | 1 |

| 73 | PEX150×750 crusher | Q: 8.35T/h; N: 15kW | 1 |

| 74 | B360 horizontal material sealing machine | L = 5.5m; Q: 21T / h; N: 5.5kW | 1 |

| 75 | TH315 bucket lifter | C: 22.563m; 11kW | 1 |

| 76 | KSIII-400 top machine | L=31.800m; 11kW | 1 |

| 77 | HD8948C single bag dust collection | Q: 2000-3000m3/h; 5.5kW-2P | 1 |

| 78 | CWB-3 horizontal electric dust collection | Q: 4500-7200m3/h | 1 |

| 79 | DFF150 electric flap valve | 0.37-0.55kW | 1 |

| 80 | C648No.5C fan | Q: 7200 m3/h; P: 1850 Pa; N: 7.5 kW | 1 |

| 81 | LS200 screw machine | L=6.5m | 1 |

| 82 | Gate | 400×400 | 4 |

| 83 | GZ-3 electric vibration machine | Q: 25T/h | 4 |

| 84 | TD-75 tape machine | B500×30m; 11kW | 1 |

| 85 | PE250×400 crusher | 250×400 Q: 4-14m3/h; N: 15kW | 1 |

| 86 | TH315 bucket lifter | C: 19.491m; Q: 35m3/h; 11kW | 1 |

| 87 | TH315 bucket lifter | C: 17.433m; Q: 35m3/h; 11kW | 1 |

| 88 | Gate | 300×300 | 3 |

| 89 | Belt scale TDG650 | Q: 24T/h | 1 |

| 90 | Belt scale TDG500 | Q: 6.5T/h | 1 |

| 91 | Belt scale TDG500 | Q: 1.5T/h | 1 |

| 92 | MB2275 mill | Φ2.2×7.5m; Q=16T/h; | 1 |

| 93 | DEF400S electric flap valve | Q: 20-60T/h; N: 0.75kW | 1 |

| 94 | CLK2×6 diffused cyclone dust collector | Q: 12120-13500m3/h | 1 |

| 95 | DFF150 electric flap valve | 1 | |

| 96 | CWB6 horizontal electric dust collection | Q: 14200-17000 m3/h; loc>99.5% | 1 |

| 97 | LS400 screw machine | L: 13.500m; Q: 36.2 m3/h; N: 5.5kW | 1 |

| 98 | Y5-48-No.6.3C fan | Q: 12030 m3/h; P: 2592Pa; N: 15kw | 1 |

| 99 | TH315 bucket lifter | C: 21.027m; 11kW | 1 |

| 100 | QLL4.0 powder separator | N: 30kW; 3.5m | 1 |

| 101 | DFF400S electric flap valve | 0.75kW | 1 |

| 102 | LS400 screw machine | L: 13.500m; Q: 36.2m3/h N: 5.5kW | 1 |

| 103 | TH315 bucket lifter | C: 15.395m; Q: 35 m3/h; 11kW | 1 |

| 104 | TH315 bucket lifter | C: 21.539m; Q: 35 m3/h; 11kW | 1 |

| 105 | LS400 screw machine | L: 23.000m; Q: 36.2m3/h N: 11kW | 1 |

| 106 | LS400 screw machine | L: 25.000m; Q: 36.2m3/h N: 11kW | 1 |

| 107 | LS400 screw machine | L: 24.000m; Q: 36.2m3/h N: 11kW | 1 |

| 108 | HD8948C single bag dust collector | Q: 2000-3000m3/h; N: 5.5kW+0.75kW | 1 |

| 109 | Gate | 300×300 | 6 |

| 110 | Rigid impeller feeder | 300×300 | 6 |

| 111 | LS400 screw machine | L: 21.500m; Q: 36.2m3/h N: 11kW | 1 |

| 112 | TH315 bucket lifter | C: 14.371m; N=11kW | 1 |

| 113 | D870 rotary screen | N: 2.2 kW; Q: 30 T/h | 1 |

| 114 | G4201 packaging machine | Q: 30T/h; N: 11kW | 1 |

| 115 | MW-N-140-SP bag filter | Q: 8400-16800; N: 3kW + 2.2kW + 1.5kW | 1 |

| 116 | Butterfly valve | Φ200 | 3 |

| 117 | 4-72-11No.5A fan | Q: 11830 m3/h; P: 2844 Pa; N: 15 kW | 1 |

| 118 | LS-200 screw machine | L=5m; N: 2.2kW | 2 |

| 119 | LS400 screw machine | L = 4.5m; Q: 36.2 m3/h; N: 5.5kW | 1 |

| 120 | tape dispenser | B800×4000; N: 3kW | 1 |