Fly Ash Handling System

What is Fly Ash Handling System

The Fly Ash Handling System is a type of integrated engineering system used to safely collect, transport, store, and pre-treat fly ash in various coal related industries, such as coal-fired thermal power plant, industrial coal-fired boilers, coal-fired hot water boilers and heating boilers, coal-fired kilns: such as cement rotary kilns (some use pulverized coal as fuel), lime kilns, ceramic kilns, etc. Its core goal is to achieve harmlessness and resource utilization of fly ash generated from burning of coal.

How is Coal Fly Ash Generated

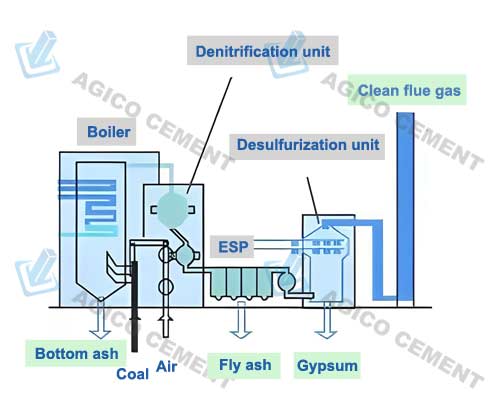

Fly ash, a common byproduct of coal-fired thermal power plants, is generated during the combustion process in power plant boilers. These fine ash particles pass through the flue into settling chambers and dust collectors, where they are ultimately collected and form what we call fly ash. Because power plant boilers comsums large quantities of coal continuously, the amount of fly ash produced is enormous, requiring constant removal from the ash hoppers of the settling chambers and dust collectors, and conveyed to ash silos for processing.

Fly Ash Characteristics From Coal Burning

AGICO has rich experience in offering complete fly ash handling system solutions for fly ash handling system for ash management and utilization in thermal power plant, cement plant, fly ash generated from coal burning has following characteristics:

| Characteristics | Coal Fly Ash |

|---|---|

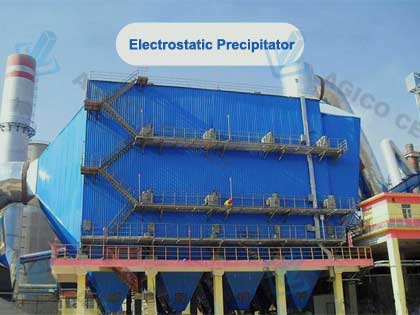

| Collection Method | Electrostatic precipitator (ESP) or bag filter |

| Appearance | Light to dark grey fine powder |

| Main Composition | Silica (SiO₂), alumina (Al₂O₃), iron oxides, CaO, unburnt carbon |

| Heavy Metal Content | Low to moderate |

| Organic Pollutants | Negligible |

| Moisture Tendency | Dry, free-flowing |

| Hazard Classification | Usually non-hazardous (depends on coal source) |

Fly Ash Handling Process and Equipments

The fly ash handling system consists of 2 parts: fly ash collection, conveying and storage system; fly ash management and utilization. As fly ash from coal burning is classified as non-hazardous waste, the handling process and equipment is more simple than fly ash from waste incineration plant.

Mechanical conveying: Fly ash is generated and collected from the reaction tower, ESP and bag dust collector, and is discharged from the ash hopper and bag dust collector. It is first collected by the scraper conveyor (located at the bottom of the reaction tower and baghouse dust collector), and then transported to the bucket elevator by the scraper conveyor. Finally, it is lifted by the bucket elevator and transported to the ash bin for storage. Pneumatic conveying method is more suitable for fly ash conveying and is widely used in many projects.

1. Coal Fly Ash Collection at ESP or Bag Filter

When high-temperature flue gas passes through ESP or baghouse dust collector, fly ash is collected by electrodes charge and dislodged into ESP hoppers, or physically stopped by bag filter with 99% efficiency.

- Flue gas passes through ESPs.

- Electrodes charge ash particles and collect them on plates.

- Plates are periodically rapped to dislodge ash into ESP ash hoppers.

2. Pneumatic Conveying from Ash Hoppers

When ash hoppers is full, Pneumatic conveying method is adopted to extract and transmit fly ash to collection silo or tank, compressed air (0.3–0.6 MPa) pushes fly ash through sealed pipes to a storage silo, with a leak-proof design (dust concentration <10 mg/m³).

Mechanical conveying is also an economical option for short-distance transmission. Screw conveyors/tube chain conveyors are used for conveying from dust collector hopper to storage silo).

- Vacuum (negative pressure) systems or pressure systems convey the ash.

- Discharge gates or rotary airlocks control ash flow.

What is Pneumatic Conveying of Fly Ash

It is a fluidized device that uses airflow to transport fly ash in a closed pipe. It can also be used in casting, metallurgy, chemical industry, building materials and food processing. Its core structure includes components such as receiver, conveying pipe, separator and fan. According to the working pressure, it can be divided into suction conveying (low/high vacuum), pressure conveying (high/low pressure) and pulse conveying system.

- Vacuum type: Fly ash is sucked to an intermediate collection silo.

- Pressure type: Fly ash is pushed to a storage silo using compressed air.

3. Fly Ash Storage in Silos

Fly Ash silos are the terminal storage facilities of pneumatic ash handling systems. It can be made of concrete structure or steel. With a sealed container structure to keep the fly ash dry and typically have a storage capacity sufficient to store 24-48 hours of ash discharge. Typical fly ash silos are constructed of steel or concrete and equipped with dust removal equipment and a conveying system.

The fly ash silos are divided into raw ash, coarse ash, and fine ash storage bins for tiered storage. A pulse bag dust collector is installed on the silo roof to separate air and ash.

- Large steel silos store fly ash until transport.

- Equipped with aeration pads to prevent bridging.

- Silo top bag filters remove dust from vented air.

Coal Fly Ash Management and Utilization

Fly ash management and utilization technology has been ugrading, for now, fly ash from coal can be utilized in 3 major methods: Building Materials, Engineering filling and functional material, Concrete Material and Metal Extraction. Here is a table of brief info of each methods and their related equipments, if you want to more info, contact now to get help from AGICO engineer team.

Fly Ash Utilization Methods

| Classification | Method | Principle | Related Equipment | Features/Notes |

|---|---|---|---|---|

| Utilization of building materials | Cement and concrete admixtures | SiO₂ and Al₂O₃ in fly ash react with Ca(OH) ₂ to improve strength and durability | Fly ash dryer, grinding mill, metering and conveying system, concrete mixing station | Mature application, large consumption volume, need to control activity and fineness |

| Fly ash bricks/aerated concrete | Fly ash is used as a silicon and aluminum raw material, mixed with lime, cement, and gypsum, and solidified by autoclaving. | Silo, metering system, twin-shaft mixer, mold, autoclave | Low cost and can be mass-produced, but the raw material ratio requirements must be met | |

| Engineering filling and functional materials | Roadbed filling and mine backfill | Fly ash is used as a lightweight filler to improve load bearing, or combined with cement/lime to stabilize the roadbed. | Bulk trucks, spreaders, mixers | Low-quality fly ash can be used, but dust and infiltration must be prevented |

| Preparation of microbeads and ceramsite | Recycle fly ash floating beads, or granulate and burn ceramsite to use as lightweight aggregate | Sorting machine, granulator, rotary kiln | Value-added utilization, the product market price is high, but the output is limited by the properties of fly ash | |

| Resource deep processing | High-performance concrete mineral admixtures | Preparation of ultra-fine fly ash (>500 m²/kg) to improve the performance of high-performance concrete | Ball mill/vertical mill, air classifier, collector | High added value, suitable for special projects, but high equipment investment |

| Extraction of alumina and rare metals | Acid leaching/alkaline leaching to extract aluminum oxide, gallium and other valuable metals | Leaching reactor, filter, sedimentation tank, evaporation crystallizer | The technology is complex and the economic feasibility depends on the market price and fly ash composition | |

| Final disposal | Abandonment/Storage | When the fly ash cannot be fully digested, safe storage | Dry ash storage, wet dump, spray dust suppression system, anti-seepage lining | Strict dust and leachate prevention are required, and long-term monitoring of environmental impact is required. |