Spiral Conveyor

- Application: a kind of conveying equipment widely used in chemical, building materials, grain and other departments

- Material: mainly used for conveying powdery, granular and small materials

Case:

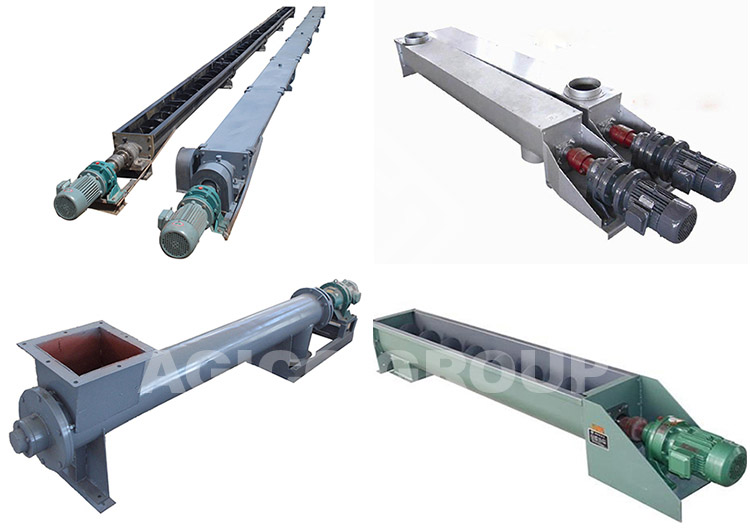

The screw conveyor is divided into ordinary spiral, pipe spiral and shaftless spiral according to the different materials. Screw conveyors are used in a wide range of applications. The spiral blade of the screw conveyor has features of high coaxiality, good rigidity, stable operation, high reliability, long service life, strong adaptability and convenient installation and maintenance. Our screw conveyors of different specifications for Inner Mongolia and Ningxia are used to transport fine powder materials on the active lime production line. Screw conveyor provided for Shandong Taierzhuang is used to transport cement in cement plant cement powder system. The stainless steel shaftless screw provided for the Tarim Oilfield in Xinjiang is used to transport the oil pool sludge into the dryer.

Screw Conveyor Description:

Screw conveyor, or spiral conveyor is a kind of conveying equipment widely used in chemical, building materials, grain and other departments. It is mainly used to transport powdery, granular and small block materials. It is not suitable for conveying materials that are prone to deterioration, viscous and agglomerate. The ambient temperature used by the screw conveyor is -20~50 °C; the conveying length is generally less than 40m, and the longest is not more than 70m. Compared with other conveying equipment, screw conveying has the advantages of simple structure, small cross-sectional size, good sealing performance, multi-point loading and unloading in the middle, safe and convenient operation and low manufacturing cost. Its disadvantages are that the parts are worn more seriously, conveying volume is lower, power consumption is large, and materials are easily broken during transportation.

Suited Materials for Screw Conveyor

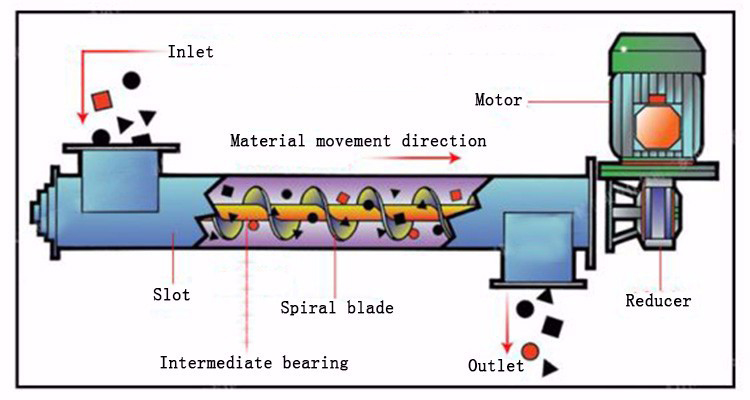

Working Principle of Screw Conveyor

When the screw shaft rotates, due to the gravity of material and friction generated by the tank wall, the material can only move forward along conveyor bottom with the pushing of blade, and the nut can not be rotated. The rotating screw acts as a translational motion. The movement of the material in intermediate bearing is dependent on the thrust of material that is moving forward.

Transport of materials in conveyor is completely a slip motion. In order to make screw shaft in a more favorable tension state, driving device and discharge port are generally placed at the same end of the conveyor, and feed port is placed as close as possible to the OTHER tail of the other end. Rotating spiral blade conveys the material, and the force of the material not rotating together with the screw conveyor blade is the weight of the material itself, frictional resistance of screw conveyor casing to the material. The blade shape has a solid surface type, a belt surface type, a blade surface type, it it depended by the material type. The screw shaft has a thrust bearing at the end of material moving direction to give the axial reaction spiral force. When the equipment length is too long, intermediate hanging bearing should be added.

Technical Parameter of Screw Conveyor

| Technology data of spiral tube screw conveyor | ||||||||

|---|---|---|---|---|---|---|---|---|

| Specification | Spiral diameter(mm) | Delivery distance(mm) | Rotating speed(r.p.m) | Max feeding capacity(m3/h) | Power(kw) | Matched reducer | Max material size(mm) | Total weight(t) |

| AG WD1215 | Φ120 | 1500 | 20-80 | 1.4 | 1.1 | ZQ250 | 20 | 0.65 |

| AG WD1225 | 2500 | 0.87 | ||||||

| AG WD1615 | Φ160 | 1500 | 15-75 | 4.8 | 1.5 | ZQ250 | 25 | 0.78 |

| AG WD1625 | 2500 | 1.03 | ||||||

| AG WD2015 | Φ200 | 1500 | 15-60 | 7.4 | 2.2 | ZQ250 | 30 | 0.92 |

| AG WD2025 | 2500 | 1.23 | ||||||

| AG WD3015 | Φ300 | 1500 | 10-45 | 21.2 | 3 | ZQ250 | 40 | 1.1 |

| AG WD3025 | 2500 | 1.38 | ||||||

Screw Conveyor Structure and Composition:

The main body of the screw machine is composed of head bearing, tail bearing, suspension bearing, screw, casing, cover plate, driving device, base.

Performance characteristics:

- large volume, high speed, long service life. High speed means high productivity and reduced production cost per unit time. Wear is the main reason for limiting the life of the screw conveyor. It reduces the friction coefficient between the material and the spiral, increases the wear resistance of the screw shaft, improves the performance of the material, and can greatly improve the service life of the conveyor.

- Low energy consumption and reduced energy consumption. Most of the energy of a screw conveyor is consumed by friction losses. Therefore, reducing energy consumption is a difficult problem and development direction for research and design of screw conveyors.