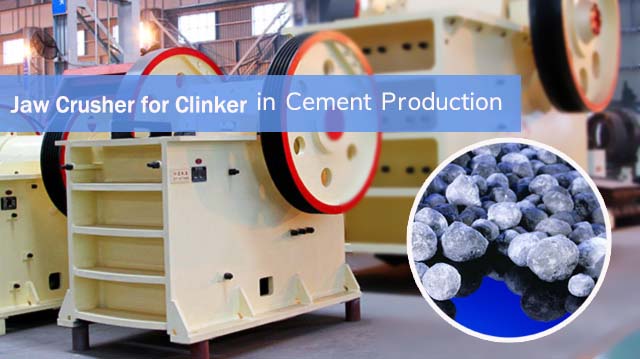

New Type Jaw Crusher for Sale from AGICO Cement Equipment

The new jaw crusher is a new generation of crushing equipment developed by the traditional E-break. While inheriting the advantages of traditional E-breaking, the machine has also made great improvements in its overall performance and green production operation. However, although this improvement has certain industry commonalities, it also has its own technology strength related. Some manufacturers have improved the output of the new jaw crusher and the noise has dropped significantly through improvement and large cost investment. However, some manufacturers have limited improvement in new jaw crusher. Although the appearance is different from that of previous generation jaw crusher, it is not easy to say whether the technology upgrade has been achieved.

Advantages of New Type Jaw Crusher

- Performance 1: The design of the “V” type crush deep cavity not only realizes the operation without broken corner crushing operation, but also improves feeding capacity and productivity of E broken machine.

- Performance 2: Compared with old-fashioned E-breaking equipment, new jaw crusher has a larger adjustment range of discharge opening. In addition, the gasket-type discharge opening adjustment device is reliable and convenient, so it can meet production needs of different users.

- Performance 3: The new jaw crusher parts are selected from high-quality wear-resistant materials, so pressure resistance and wear resistance of new jaw crusher are certain compared to original crushing equipment. It is to be stronger.

- Performance 4: When new jaw crusher is working, there will be low noise and less dust. In addition, compared with the old-fashioned equipment, energy saving of the equipment can reach 15%~30%, which can fully meet the current green production demand.

New Type Jaw Crusher Price

First of all, the new jaw crusher is a new type of environmentally friendly crushing machine, so the price of new jaw crusher is definitely more expensive than ordinary type of equipment. In many cases, the new type jaw crusher development is not as simple as adding a few tons of steel materials. The R&D investment of new equipment is an invisible and huge price. Therefore, after the new equipment is put into production, R&D investment cannot be neglected. Therefore, the new type jaw crusher equipment is more expensive.

How to Reduce Noise of Jaw Crusher

The jaw crusher is too noisy in production process, which will cause noise pollution and affect physical and mental health of the staff and surrounding residents. Therefore, the noise problem has always been one of the problems that mining machinery enterprises need to solve. How to reduce sound source of noise can be started from following aspects.

1. Install wear-resistant rubber as a lining in the impact of all the broken materials of jaw crusher to avoid excessive noise and noise.

2. If jaw crusher is installed on anti-vibration base, the noise of whole machine can be reduced by about 15~25dB.

3. Improve processing and assembly accuracy of jaw crusher to reduce noise generated by machine vibration and friction.

4. The drive surface of jaw crusher feed plate and feed funnel and the frame are covered with damping material to reduce noise radiation area.

5. The noise elimination channel is installed in the original discharge port of the machine to prevent the internal noise from radiating outward.

6. Use directivity characteristics of sound source to control noise. For example, high-pressure boiler exhaust steam, blast furnace air release, oxygen generator exhaust and other discharge outlets face wilderness to reduce the impact on the environment.

7. Eliminate machine failures in time. Machine failure can lead to additional noise. For example, if belt is deflected, the sound of product belt will be hit. For example, there is a problem with the discharge. Excessive stone hits the noise generated by the crusher, and the machine foundation drops, causing the machine to resonate. If such noise occurs, you should contact the technician at the first time to resolve the fault and avoid further losses.